Selected as a 2022 Outstanding Small Business Supplier to Lockheed Martin and have been selected as a GROWFL Florida Companies to Watch 2023 Awardee!

Data Graphics Inc. Is One of the Top 10 Metalphoto® Converters in the Nation

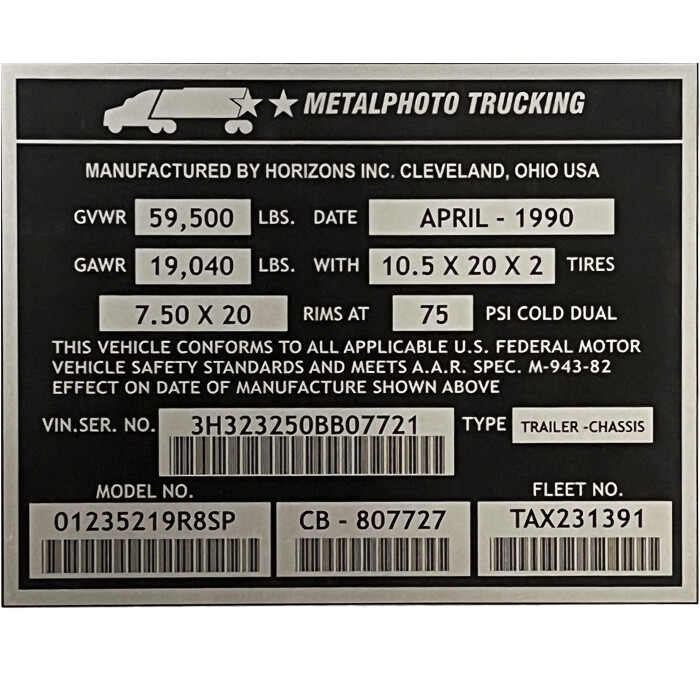

Data Graphics Inc. has been a Metalphoto Certified Converter since 2016, capable of producing metalphoto nameplates that meet MIL-STD-130 n, ASTM B209 -10 standards.

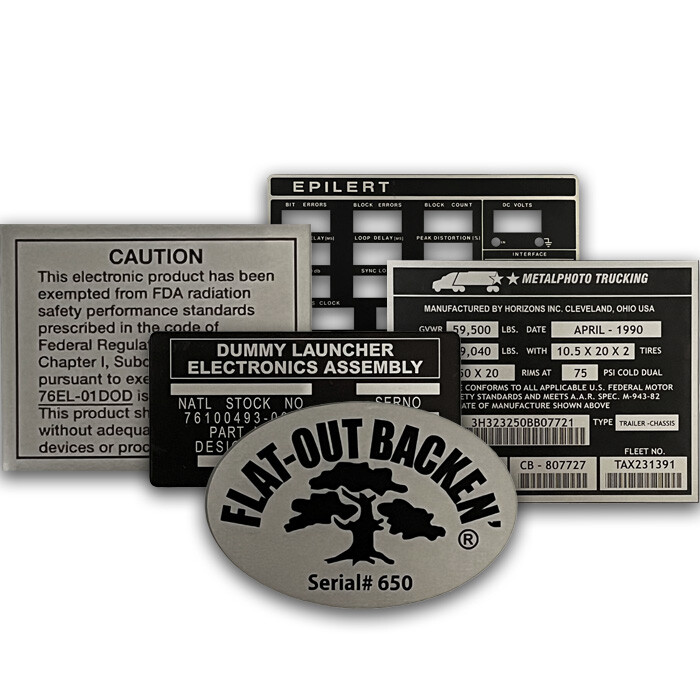

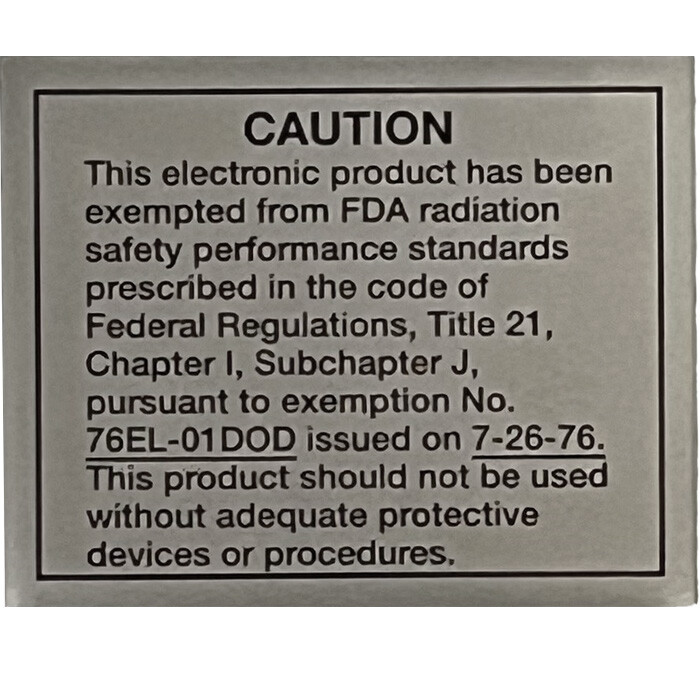

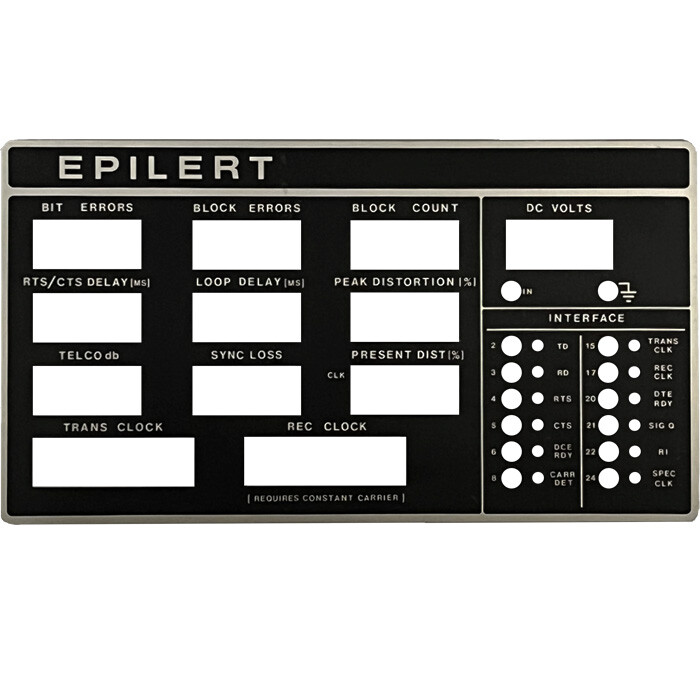

The Highest Resolution Metallic Print Solution is a Metalphoto Nameplate. It meets mil-std-130 n, ASTM B209 -10, and UL 969 Standards

Cross-section of Metalphoto Nameplate. The Imbedded Image Makes Us mil-std-130 n, ASTM B209 -10, and UL 969 compliant.

While we can digitally print, screen print, etch, and engrave metallic prints in a wide variety of ways, we recognize the metalphoto process to be the highest quality and most durable way to create a metallic print. In harsh environments, durable substrates are required. Rugged anodized aluminum is the obvious choice, and the metalphoto process provides the highest quality printing options. The metalphoto process is vastly superior to stainless steel or traditional anodized aluminum. It combines beautiful, fine detail not available through other methodologies, with durable functionality, and is 25 Year Exposure Certified. The metalphoto process uses a digital-capable machine to develop a photo on the inner layer of a sheet of photosensitive anodized aluminum. The silver halide image is permanently sealed within the anodic layer, making it nearly impervious to the elements. Metalphoto nameplates have great features, combining the durability of anodized aluminum with the highest resolution, photograph quality printing. If you are unsure whether the metalphoto process is the right printing methodology for you, please feel free to phone our knowledgeable team at 800-639-4316, or select the relevant tab. We will cover:

- The Advantages of the Metalphoto Process

- Noteworthy Applications

- How the Metalphoto Process Works

- Metalphoto Nameplate Specs

- Why Choose Data Graphics for Your Metallic Print Needs?

Metalphoto Plates FAQs

What are Metalphoto® nameplates, and what makes them unique?

Metalphoto® nameplates are nameplates made using a unique manufacturing process called Metalphoto®. This process involves embedding high-resolution graphics and text into anodized aluminum, creating a durable, long-lasting, and visually appealing nameplate solution.

How are Metalphoto® nameplates different from other types of nameplates?

Metalphoto® nameplates stand out for their exceptional durability and image clarity. The Metalphoto® process ensures that the graphics and text are sealed within the anodized aluminum, protecting them from harsh environments, UV radiation, chemicals, and physical abrasion. This makes Metalphoto® nameplates highly resistant to fading, scratching, and degradation.

What are the benefits of using Metalphoto® nameplates for industrial applications?

Metalphoto® nameplates are well-suited for industrial applications due to their durability and resilience. They can withstand extreme temperatures, moisture, chemicals, and other harsh conditions commonly found in industrial environments. Additionally, their high-resolution graphics ensure clear and readable identification, facilitating efficient asset tracking and management.

Can Metalphoto® nameplates be personalized with variable data or serialized information?

Yes, Metalphoto® nameplates can be personalized with variable data or serialized information. The Metalphoto® process allows for high-resolution imaging, enabling the inclusion of serial numbers, barcodes, QR codes, or any other variable information required for unique identification or tracking purposes.

How should Metalphoto® nameplates be maintained to preserve their appearance?

Metalphoto® nameplates require minimal maintenance to preserve their appearance. Regular cleaning with mild soap and water or non-abrasive cleaners is typically sufficient to remove dirt or grime. Avoid using harsh chemicals or abrasive materials that can damage the anodized aluminum surface.

Qualified to Deliver to Your Exact Specifications