Asset Tracking Made Easy: Using Custom Barcode Labels for Smarter Inventory Control

In high-stakes industries such as aerospace, defense, and manufacturing, asset visibility is more than a convenience. It’s a requirement. Every tool, part, and component must be traceable, auditable, and integrated with internal systems for maximum efficiency and compliance. That’s where custom barcode labels become indispensable.

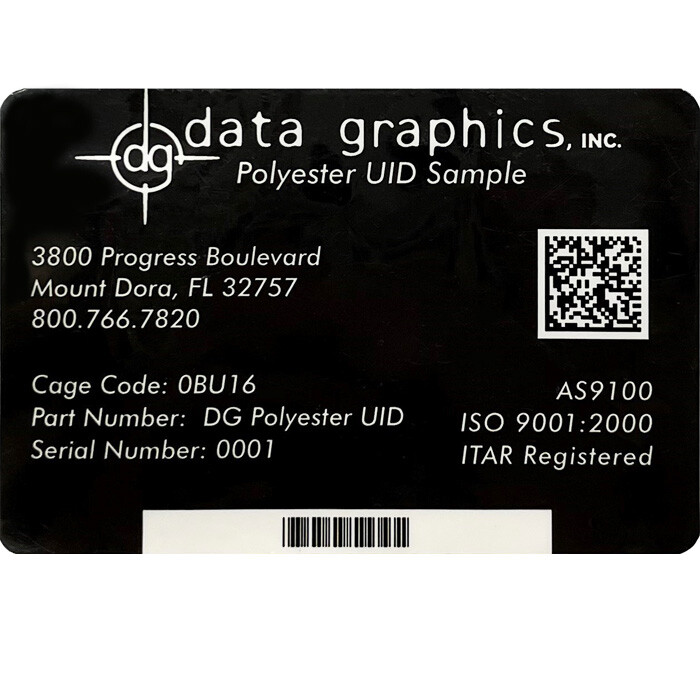

At Data Graphics, Inc., we specialize in precision-engineered identification solutions that help organizations across the U.S. track their assets with confidence. From rugged barcode nameplates to serialized tags, our products support real-time data integration and lifecycle visibility, giving engineers, procurement managers, and facility teams complete control over their inventory.

Why Smart Asset Tracking Is a Strategic Imperative

In technical environments, even a small inventory error can create cascading delays, lost productivity, or regulatory exposure. A well-designed asset tracking system delivers:

Traceability: Know where assets are and where they’ve been.

Loss Reduction: Prevent unauthorized movement or misplacement.

Data Reliability: Remove manual entry errors from records.

System Integration: Link physical inventory to ERP and WMS platforms.

Traditional approaches like spreadsheets or paper logs are no match for barcode-based automation. Scanning technology ensures accurate, real-time updates, and seamless handoffs across departments.

Understanding Custom Barcode Labels

Custom barcode labels are not generic tags. They’re engineered to your exact operational needs. Each label encodes data like serial numbers, part IDs, or asset locations into a machine-readable format. When scanned, this data instantly updates your systems, reducing human error and cycle times.

At Data Graphics, Inc., we allow clients to customize every aspect of their label:

Material: Metal, polyester, vinyl, polycarbonate

Adhesive: Standard, high-strength, removable

Shape & Size: Tailored to fit equipment surfaces

Serialization: Unique IDs, lot numbers, MIL-STD-130N compliance

Graphics: Logos, warning symbols, or color coding

These details ensure the label fits your environment, whether it’s a high-temperature aerospace facility, an outdoor utility site, or a cleanroom production line.

Enhancing Traceability with Scannable Data

Tracking assets manually introduces gaps. With custom barcode labels, traceability becomes automated, auditable, and dependable across all asset types.

Fast, Precise Identification

Scanning retrieves accurate data instantly:

- Asset condition

- Location

- Custodian or responsible party

- Maintenance status

- Order fulfillment state

For engineers and technicians, this means less downtime and faster diagnostics. For procurement managers, it means accurate records at every phase.

Complete Historical Visibility

Barcode scans create a digital chain of custody, showing where and when an item moved or changed hands. This supports:

- Internal and third-party audits

- Scheduled servicing

- Compliance tracking

- Theft or loss investigations

High-value tools, mobile diagnostic gear, or leased equipment benefit greatly from this level of oversight.

Eliminating Manual Entry Risks

Data entry errors lead to costly mistakes. By scanning barcodes, teams capture consistent, clean data, minimizing issues with stock discrepancies, unrecorded usage, or duplicate entries.

Minimizing Loss with High Visibility

Asset loss isn’t just about theft. It’s about disorganization, inefficient handoffs, and undocumented transfers. Barcode labels address these challenges with:

Inventory Accuracy

Barcode-enabled counts eliminate guesswork and reduce:

- Inventory shortages

- Duplicate orders

- Excessive holding costs

This is essential for Just-In-Time (JIT) environments, field-based operations, or any organization seeking to optimize its supply chain.

Improved Location Control

Assets that move frequently between workstations, job sites, or departments can easily go missing. Labels help teams:

- Confirm item location in real-time

- Scan assets into and out of locations

- Identify bottlenecks or misplaced tools

Barcode systems reduce time wasted searching for critical equipment and prevent interruptions to production or service schedules.

Custody Assignment and Accountability

With barcode scans tied to user IDs, accountability becomes transparent. Equipment misuse, unauthorized borrowing, or unclear ownership is significantly reduced.

ERP and Inventory System Integration

Barcode labels bridge the gap between the physical world and enterprise software. Data Graphics’ labels are designed to integrate with most major systems, including ERP, WMS, CMMS, and inventory platforms.

Real-Time Synchronization

Scans immediately update your system, eliminating:

- Delayed status changes

- Misaligned spreadsheets

- Cross-departmental communication errors

Procurement, logistics, and operations all have the same real-time view.

Better Forecasting and Planning

Barcode data helps decision-makers:

- Trigger accurate reorders

- Predict maintenance needs

- Analyze part usage trends

- Spot inefficiencies early

With the right data flowing into your software, asset tracking becomes a tool for strategic growth, not just recordkeeping.

Labels Built for Harsh Industrial Environments

Barcode labels must survive more than a clipboard or desktop. In many sectors, they’re exposed to abrasion, solvents, vibration, UV exposure, and temperature extremes. At Data Graphics, Inc., we engineer labels to perform in mission-critical conditions.

Material Options Include:

Metalphoto® Anodized Aluminum: Mil-Spec durability

Polyester and Vinyl: Chemical and solvent resistance

Polycarbonate: Extreme temperature tolerance

Labels maintain legibility after thousands of scan cycles, cleanings, and environmental exposures.

Adhesive and Finish Customization

We optimize adhesives for:

- Painted surfaces

- Plastics and composites

- Powder-coated metals

- Textured machinery

Finishes like UV laminates, matte coatings, or tamper-evident seals extend lifespan and protect against wear.

Scanning Efficiency: Design Matters

High-Resolution Printing

Our printing systems create clean, high-contrast barcodes that scan accurately even at reduced sizes, ideal for space-limited assets or dense data fields.

Right Barcode Format for the Job

Choosing the correct symbology enhances scan performance:

Code 39 / Code 128: Industrial and manufacturing

QR Codes: Quick access to documentation or part specs

Data Matrix / MIL-STD-130N UID: Aerospace, medical, and military compliance

We help clients select the right format for their scanners, environment, and regulatory needs.

Placement Optimization

A well-made label is only effective if it’s placed for optimal visibility and scanner access. Our team provides application guidance to ensure correct alignment and secure adhesion.

Beyond Labels: Durable Custom Asset Tags

For long-term identification, many organizations choose custom asset tags that combine barcodes with static data:

- Part numbers

- Company logos

- MIL-STD-130N UID or compliance icons

- QR links to MSDS or maintenance records

These tags are permanent, highly durable, and ideal for regulated industries, leased assets, or field equipment.

Examples include:

- Medical equipment and devices

- Military and defense tools

- Government contractor inventories

- Utility field kits

How to Implement a Custom Barcode Program

A successful deployment starts with proper planning:

Inventory Audit: Define what needs to be labeled, scanned, and tracked.

Label Design: Choose materials, adhesives, formats, and serialization.

Software Mapping: Link barcodes to ERP or asset tracking fields.

Team Training: Teach staff proper scanning and application techniques.

Monitoring: Adjust strategy based on wear patterns, usage reports, and user feedback.

Data Graphics supports clients through every stage, from prototype to full-scale deployment.

Why Choose Data Graphics, Inc. for Barcode Solutions

Since 1984, we’ve served high-compliance industries with precision identification solutions. We complete 60% of our orders ahead of schedule, operating from our state-of-the-art 25,000-square-foot facility in Mount Dora, Florida. Clients choose us for:

- Unmatched label durability and scan accuracy

- Customization for aerospace, defense, manufacturing, and medical industries

- Compliance with UL, MIL-STD-130N, ISO9001:2015, AS9100:2016 Rev D, ITAR, and more

- Responsive support and engineering consultation

Each order undergoes 100% quality inspection before delivery, ensuring you receive the precision and reliability your operations demand. We’ve earned recognition including the Gold Supplier Award from Boeing, Platinum Premier Supplier Award from Rockwell Collins, and Outstanding Small Business Supplier Award from Lockheed Martin.

Conclusion: Precision Starts With Visibility

Tracking assets doesn’t have to be cumbersome or error-prone. With custom barcode labels from Data Graphics, Inc., you gain more than a label. You gain control.

Our labels deliver:

- Trusted identification

- Real-time data flow

- ERP system integration

- Longevity in tough environments

If you’re ready to strengthen your inventory control, improve compliance, and eliminate guesswork, our team is ready to help.

Let’s Talk Custom Barcode Labels

Reach out to Data Graphics, Inc. to learn how our barcode solutions can support your asset tracking needs, whether you’re labeling medical equipment, military assets, or factory floor machinery. Our solutions are engineered to perform and built to last.