Essential Gaskets: Ensuring Tight Seals for Optimal Performance

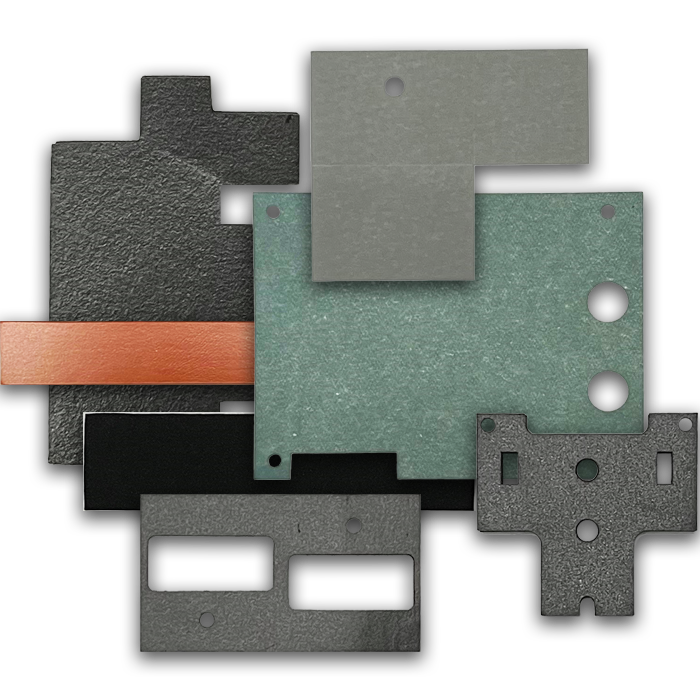

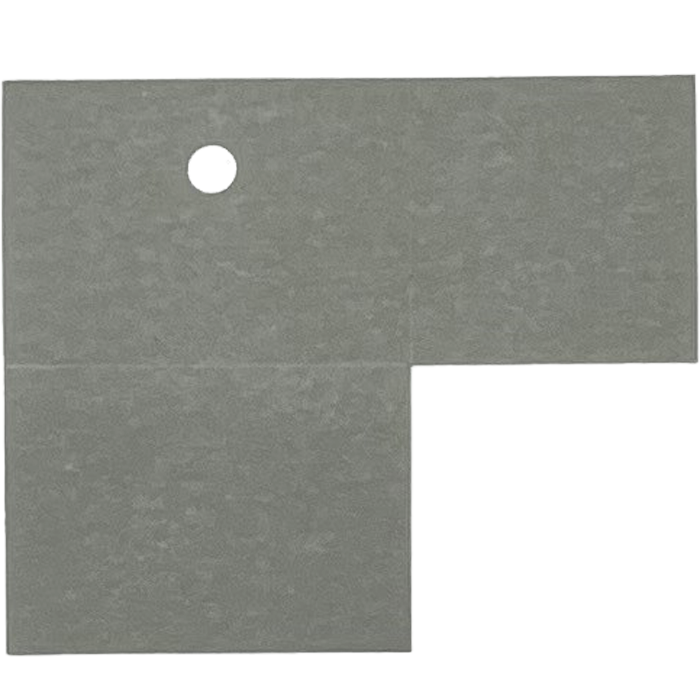

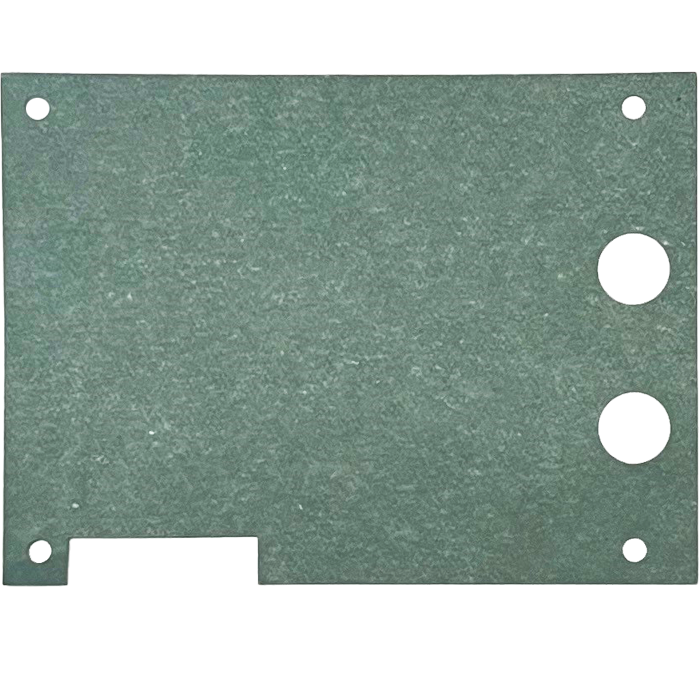

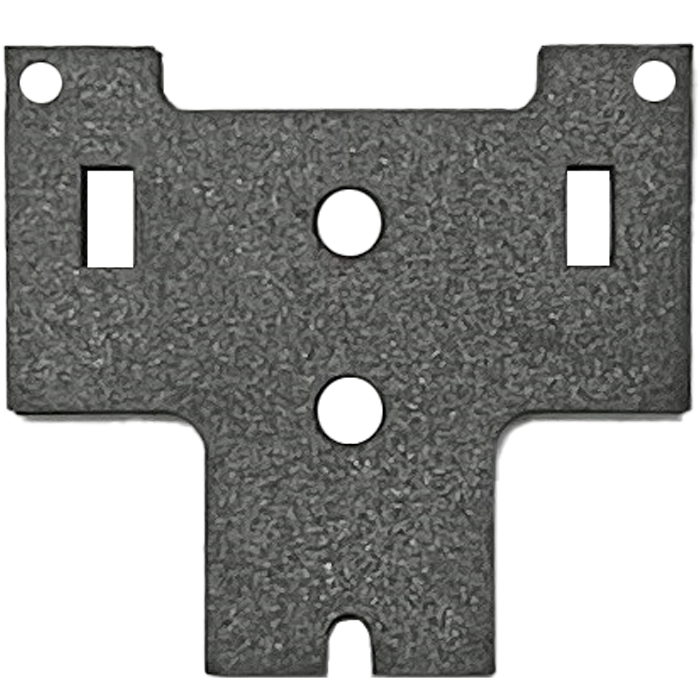

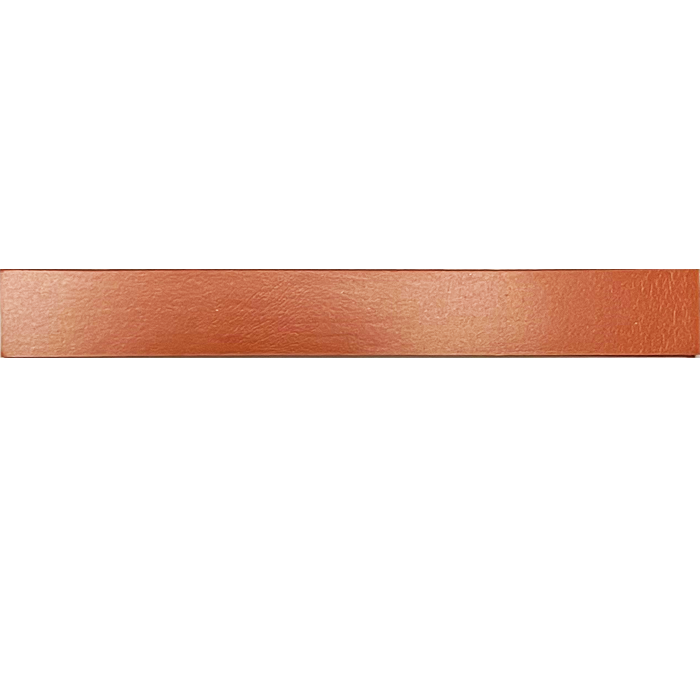

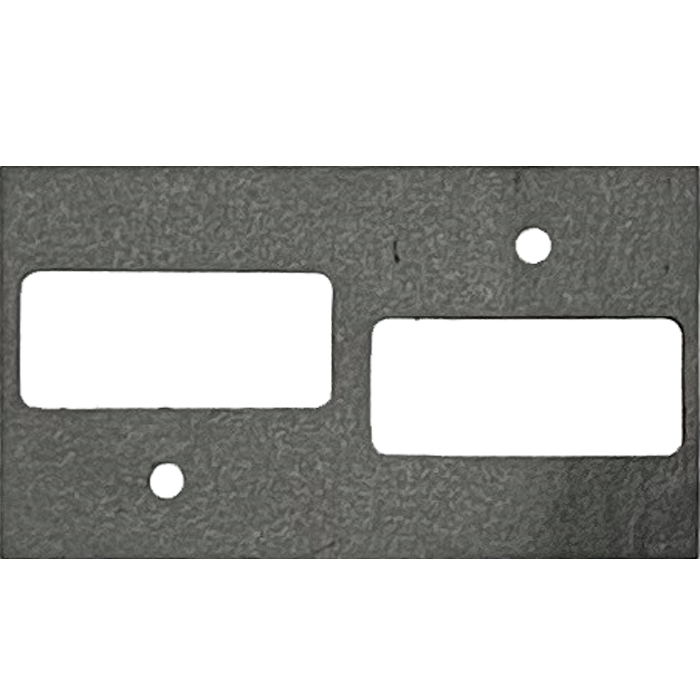

We offer Foam Gaskets and Rubber Gaskets with or without adhesive. Foam and Rubber both provide an excellent barrier and are capable of bonding for gasketing, cushioning, sealing, mounting and insulation applications. Foam gaskets can be “open cell” or “closed cell,” Whereas Rubber gaskets are “closed cell.” The “open cell” foam gaskets are usually used for vibration or shock applications, while “closed cell” foam gaskets or rubber gaskets are for environmental seals (usually when outdoor conditions are a big factor). Our foam gaskets and rubber gaskets are available in a wide range of thicknesses, hardnesses, densities and colors to meet your needs.

Regardless of your application and materials requirements (such as EPDM rubber, Neoprene, Polyurethane, Silicone, 3M VHB Foam Adhesive), we have a completely custom die cut solution that will meet your strict requirements and specifications. Our large selection of foam and rubber material and die cutting equipment allows us to create the custom solution other companies can’t match.

Some of the more common Foam Gasket Applications are:

- Insulation

- Electrical absorption

- Cushioning

- Fluid Restriction

- Noise reduction

- Weather resistance

Data Graphics can create your foam gaskets using a variety of methods. Our 25,000-square-foot facility in Mount Dora contains the most modern die-cut and printing equipment available on the market today.

The average turnaround on a job can take seven to ten business days after the design has been approved by the client.

Get a Quote today for your Foam Gaskets!

Gaskets FAQs

When are custom gaskets appropriate for my application?

Custom cut gaskets are sealing components tailored to specific shapes and dimensions for applications where standard gaskets aren’t suitable. They create a barrier between surfaces to prevent leakage of fluids, gases, or contaminants.

What materials can be used for custom cut gaskets?

A wide range of materials can be used, including rubber, silicone, paper, metal, and various plastics. Material selection depends on factors like temperature, pressure, chemical exposure, and sealing requirements. The Team at Data Graphics can work with you to determine the most appropriate material for your specific application.

What advantages do custom gaskets offer over pre-made gaskets?

With high quality design and manufacturing, custom gaskets offer superior fit and sealing performance compared to pre-made gaskets. They can be tailored to specific requirements, ensuring optimal performance in challenging environments and complex assemblies.

Can gaskets be used for food or medical applications?

Yes, certain food-grade or medical-grade materials can be used for gaskets to ensure compatibility with FDA and medical industry regulations. These gaskets provide safe and reliable sealing in food processing and medical equipment.

How long does it take to manufacture custom gaskets?

The manufacturing time varies based on factors such as complexity, material availability, and quantity. Simple gaskets may be produced quickly, while complex designs might take longer. We’ll work closely with you to determine an accurate lead time for your specific needs.

Qualified to Deliver to Your Exact Specifications