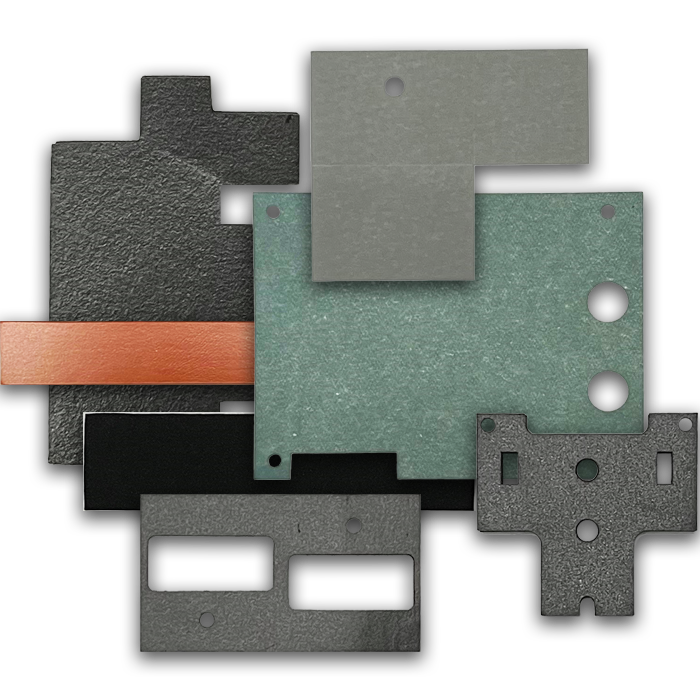

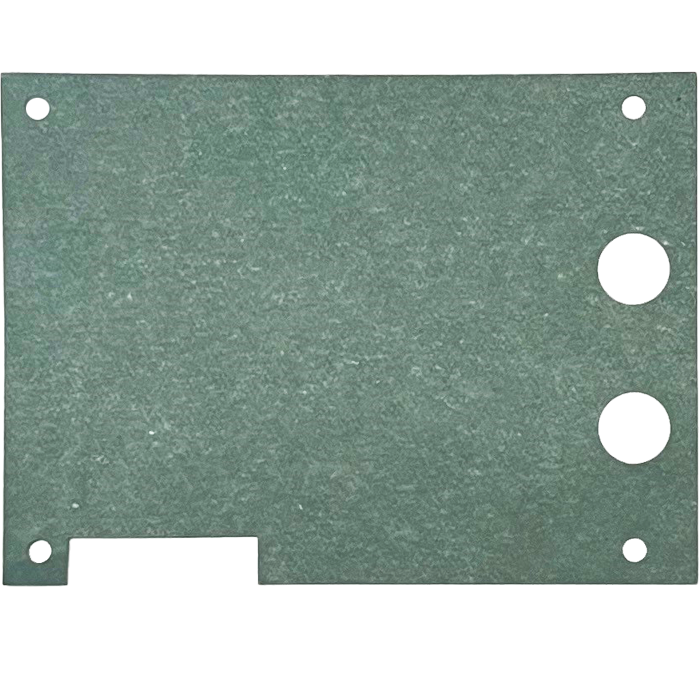

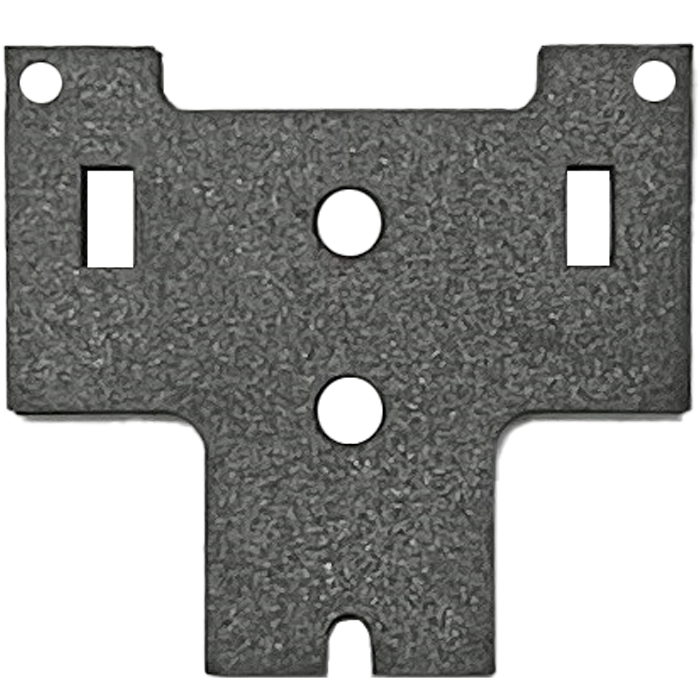

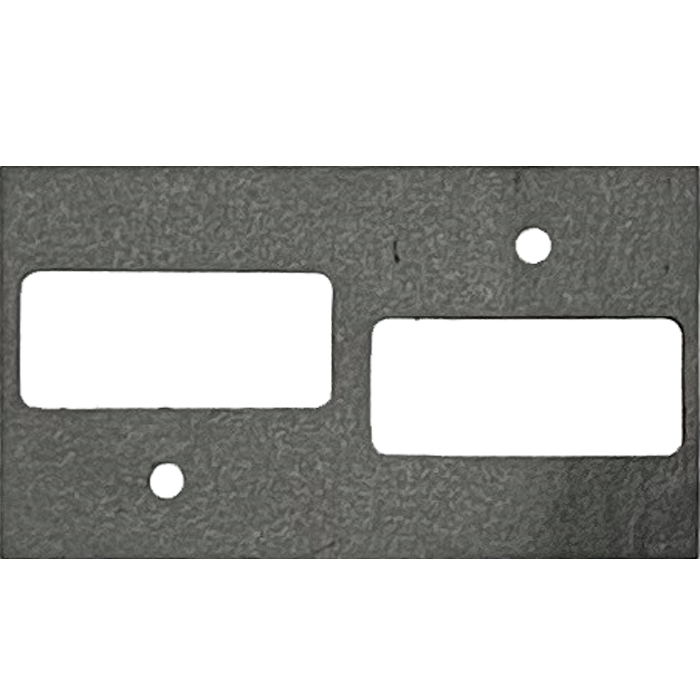

Data Graphics offers a wide variety of insulator materials for your specific needs, whether it be electrical safety, isolation, preventing short circuits, environmental protection, thermal insulation, mechanical support, or dielectric properties, there are many material options to fit your needs.

FR4 for flame retardance, chemical resistance, as well as having high electrical resistance make it a cost-effective solution when used as an insulator in electronics and PCBs.

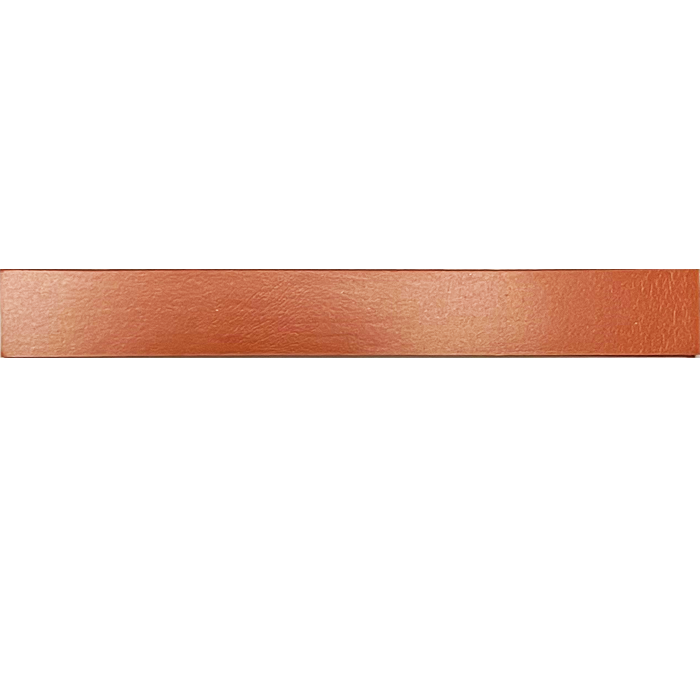

Polyurethane has many unique properties and advantages such as thermal insulation, energy efficiency, and moisture resistance, making it a versatile candidate for your insulation needs.

Silicone is also a popular choice for an insulator option in a variety of industries such as medical, aerospace, automotive and electronics. Many beneficial properties include temperature, UV, weather and chemical resistance, electrical insulation, dielectric properties, long lifespan to name a few. Silicone is also environmentally friendly and recyclable.

Many other insulator materials are also available such as thermal and gap pads. Data Graphics has a variety of methods for cutting custom shapes and sizes that include steel rule dies, lasers, CNC, digital cutting up to four feet by eight feet.

Choosing the right insulator is important to maintaining the functionality, safety and reliability of your products, contact your Data Graphics Sales Engineer to learn more about your insulator options.

Custom Die-Cut Insulators FAQs

What die-cut insulators and where are they used?

Die-cut insulators are specialized components made from insulating materials that are precisely cut into specific shapes using die-cutting techniques. They are used to prevent the conduction of electricity, heat, or sound between components, surfaces, or systems. These insulators find applications in electronics, appliances, automotive, and industrial equipment, where they play a crucial role in ensuring safety, thermal management, and noise reduction.

How does Data Graphics manufacture custom insulators?

The manufacturing of custom insulators involves using a die-cutting process, where insulating materials are cut into specific shapes using specialized machinery. The process includes arranging the material onto a press, applying pressure through a cutting die, and creating the desired shape. Depending on the material and application, additional steps such as adhesive backing or lamination can be included to enhance functionality.

Are insulators effective for noise reduction?

Yes, custom insulators can effectively add to noise reduction by serving as acoustic barriers. Materials with sound-absorbing or sound-damping properties can be chosen to create insulators that absorb or block sound waves, reducing noise transmission between components or spaces.

How does the environment impact the longevity of insulators?

Temperature variations, humidity, exposure to UV radiation, and outdoor conditions can impact the longevity of custom die-cut insulators. This makes the choice of material and design very important. For example, materials that are UV-resistant and weather-resistant are better suited for outdoor applications. In addition, extreme temperature changes might require materials with high thermal stability. If you have questions about the best materials and design for your specific application, we can help!

Qualified to Deliver to Your Exact Specifications