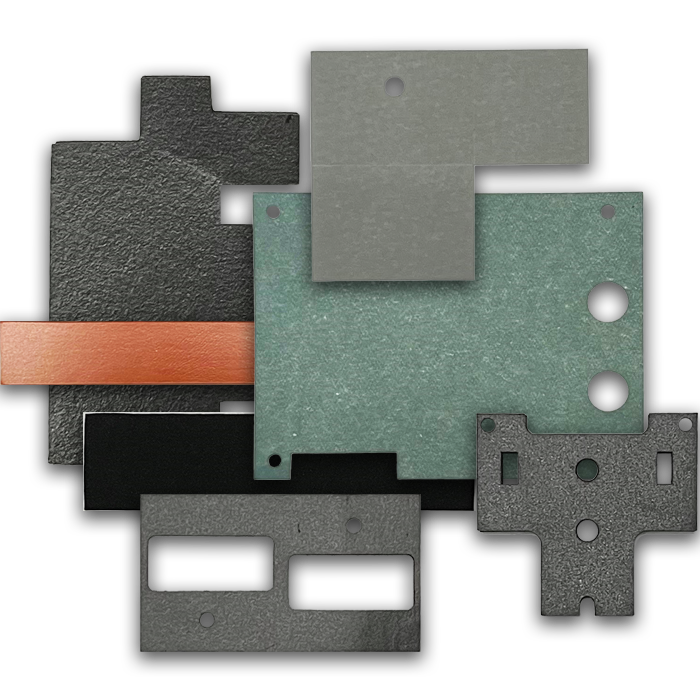

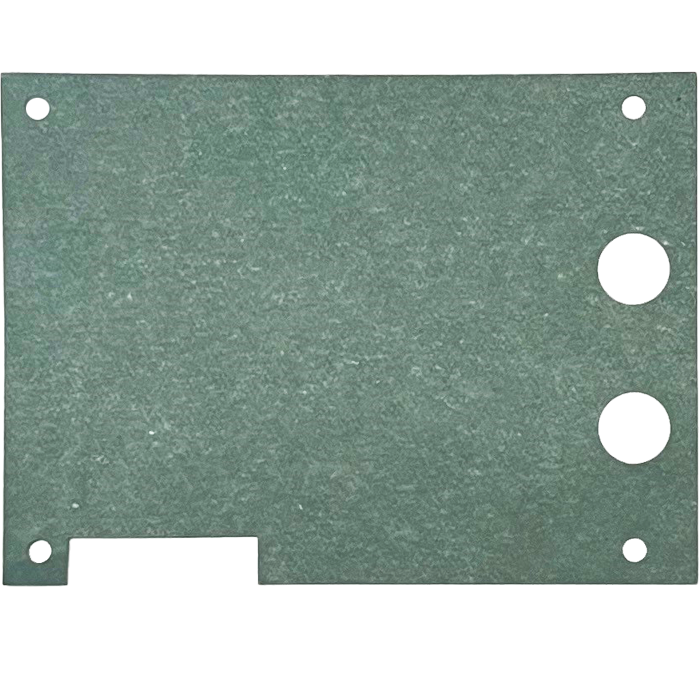

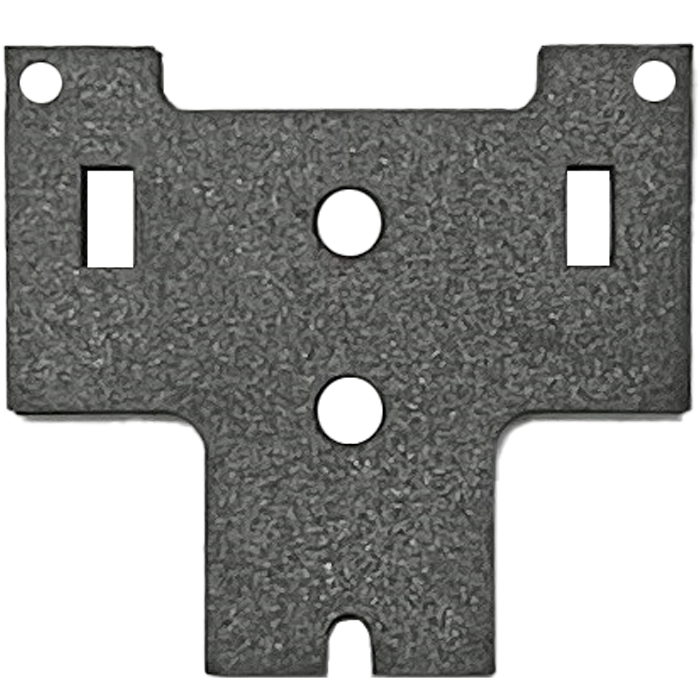

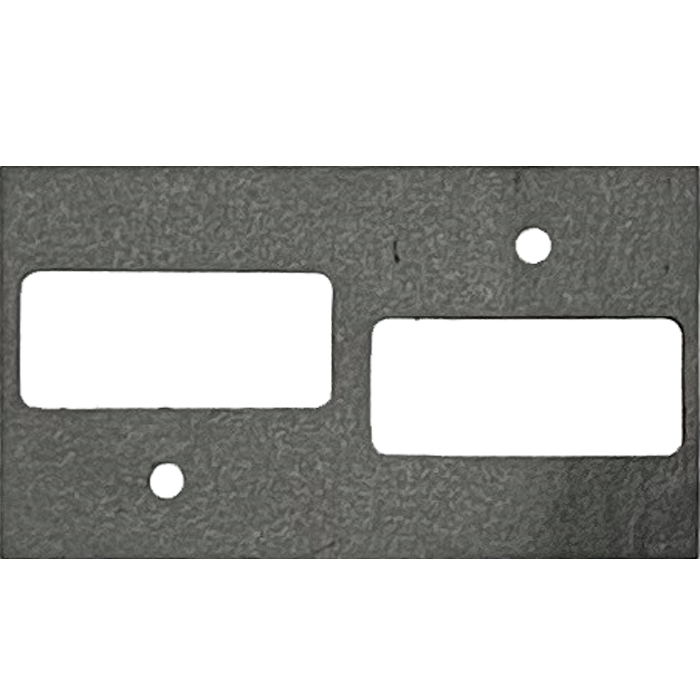

Data Graphics offers a variety of custom cut thermal pads, which are used to provide insulation as well as heat transfer. They are soft, flexible and fill microscopic gaps ensuring better contact between components. Surprisingly, many thermal or gap pads are reusable. They can be easily removed and reused.

Data Graphics has a variety of methods for cutting custom shapes and sizes that include steel rule dies, lasers, CNC, digital cutting up to four feet by eight feet.

Choosing the right thickness and thermal conductivity levels are key, contact your Data Graphics Sales Engineer to learn more about our thermal and gap pad options.

Thermal Pads FAQs

What materials are commonly used for thermal pads?

Materials like silicone-based compounds, thermally conductive epoxies, and phase change materials are commonly used for custom cut thermal pads. These materials have excellent thermal conductivity properties to facilitate efficient heat transfer.

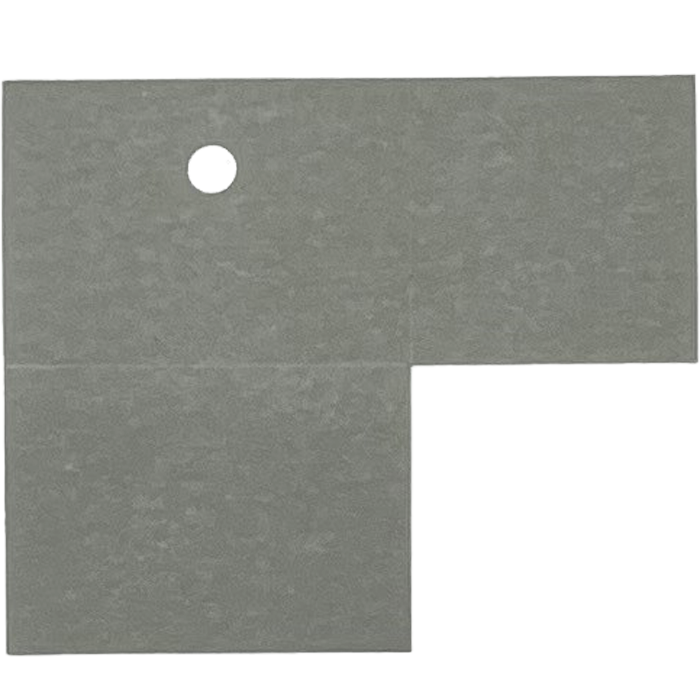

Can thermal pads be tailored to fit specific components?

Yes, that’s one of the primary advantages of custom cut thermal pads. They can be tailored to fit the exact dimensions and shapes of specific electronic components and heatsinks, ensuring optimal contact and heat dissipation.

Do custom cut thermal pads require adhesive backing?

While it’s not required, many thermal pads come with adhesive backing to simplify installation and maintain proper alignment between components. The adhesive ensures a secure attachment, enhancing heat transfer and reducing the risk of air gaps.

Why would I consider thermal pads over thermal compounds?

Thermal pads provide an advantage in terms of easy application, consistent thickness, and reduced mess compared to thermal compounds. They offer a convenient solution for applications where precision and simplicity are essential.

What factors should influence my choice of thermal pad material?

Your choice of thermal pad material depends on factors such as the desired thermal conductivity, operating temperature range, mechanical properties, and specific application requirements. Not quite sure about the best material for your specific application? One of our experts is happy to help.

Qualified to Deliver to Your Exact Specifications