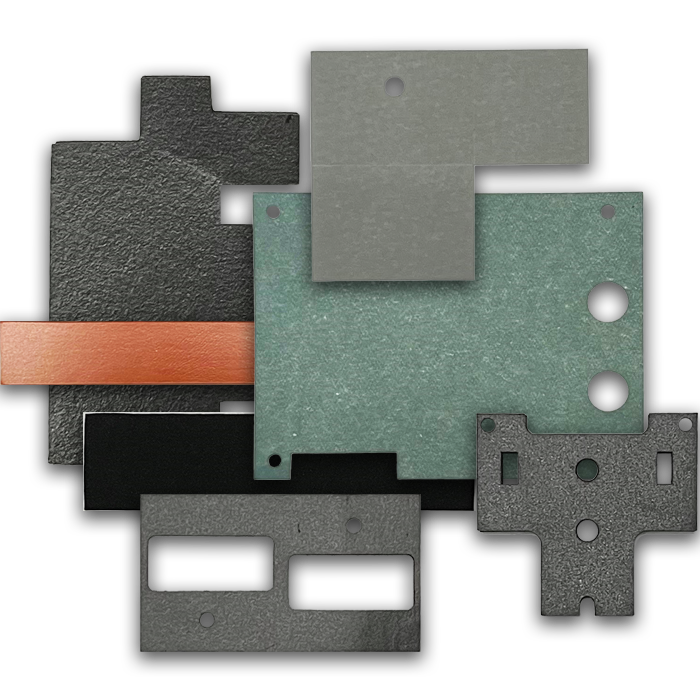

Silicone Rubber: Versatile Sealing Solutions for Reliable Performance

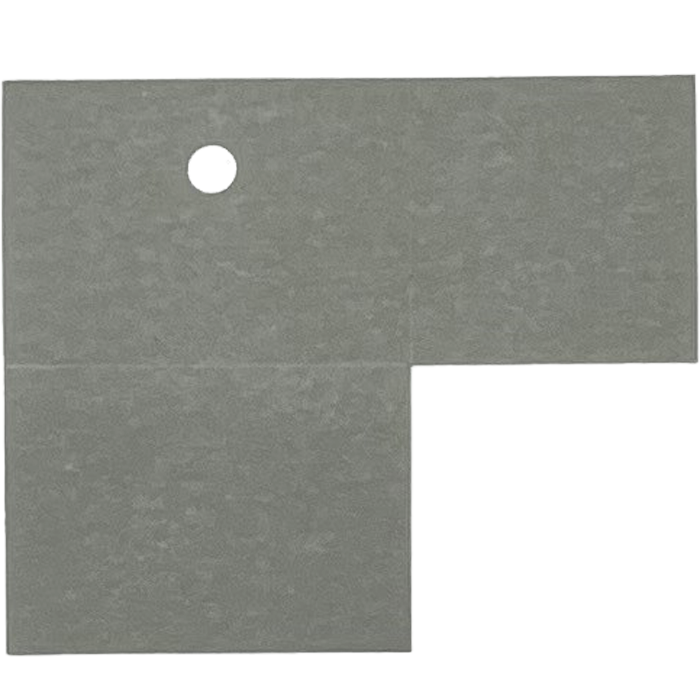

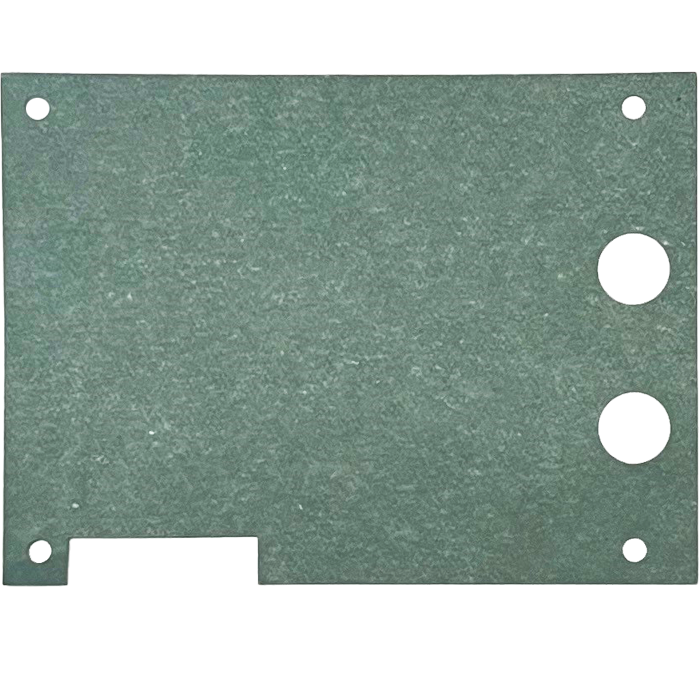

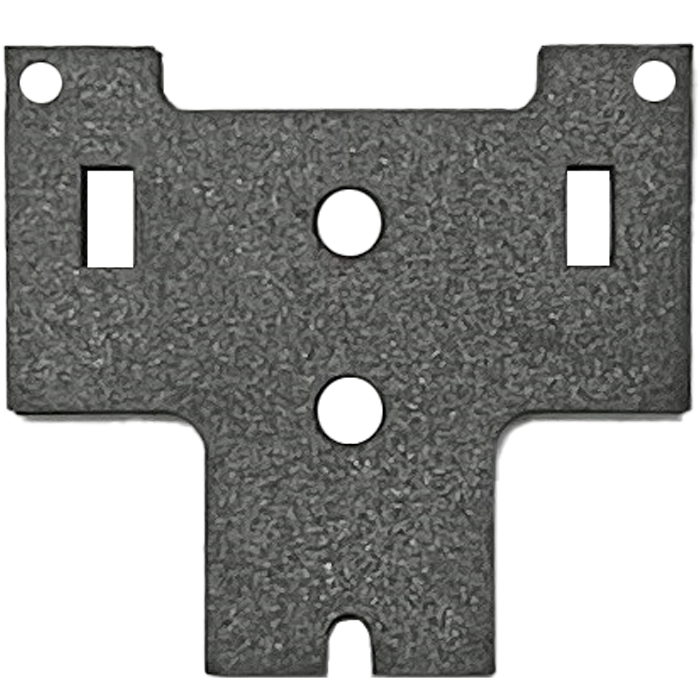

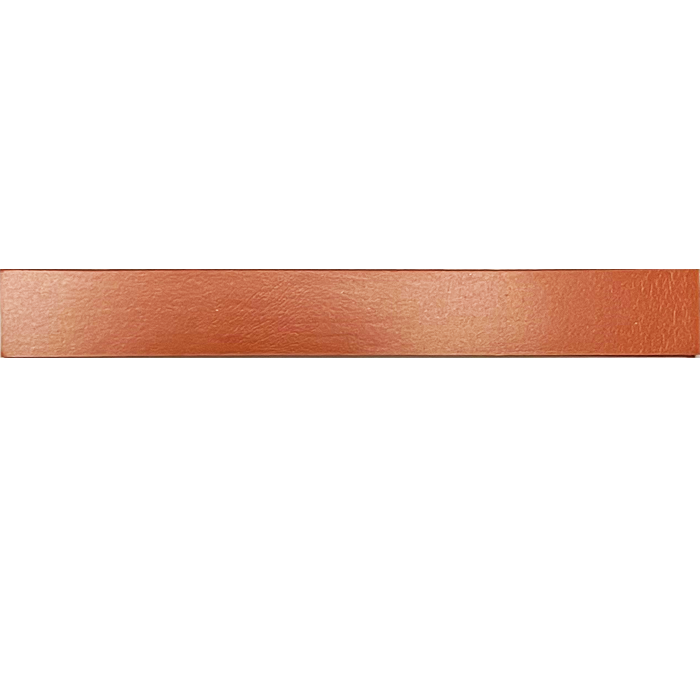

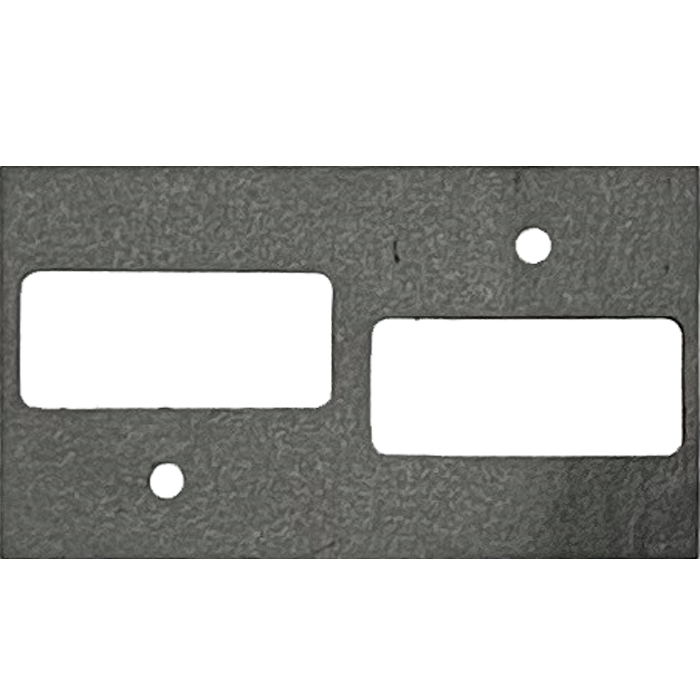

Silicone is known to endure various weather conditions. It is resistant to both extreme heat and cold temperatures, as well as ozone and oxygen attacks. Silicone gaskets are often used to prevent leaks in a wide range of applications. They can be cut from a variety of material grades. Some of the most common silicone gasket materials are: Silicone Foam Gaskets, Silicone Sponge Gaskets, Solid Silicone Gaskets, Closed Cell Silicone Gaskets, Microcellular Silicone Gaskets, and Open Cell Silicone Gaskets.

Regardless of your application and materials requirements, we have a completely custom die cut solution that will meet your strict requirements and specifications. Our large selection of materials and die cutting equipment allows us to create the custom solution other companies can’t match. We use high quality Bisco® Silicone with and without adhesive.

Some of the more common applications for silicone gaskets are:

- Water / Moisture Sealing

- Environmental Sealing

- Enclosure Sealing

- LED Lighting Sealing

- LCD / Screen Sealing

- IP Rated Enclosure Sealing

- Vibration Absorption

- Vibration Damping

- Vibration Isolation

- Noise Damping

- Noise Isolation

- Cushioning

- Gap Filling

- Shock Absorption

- Heat Dissipation / Transfer

- EMI / RFI Shielding

Data Graphics can create your silicone gasket products using a variety of methods. Our 25,000-square-foot facility in Mount Dora contains the most modern die-cut and printing equipment available on the market today. You can have your silicone gaskets created using:

- die cutting

- laser cutting

- CNC

- laminating

- slitting

- rapid prototyping

The average turnaround on a job can take seven to ten business days after the design has been approved by the client.

Get a Quote today for your Silicone Gaskets!

Silicone Rubber FAQs

What are silicone rubber gaskets and where are they most commonly used?

Silicone rubber gaskets are sealing components made from silicone rubber, a flexible and durable material known for its excellent temperature resistance and versatility. We’ve supplied these gaskets to a variety of industries such as electronics, medical devices, food processing, automotive, and others. These gaskets offer reliable sealing against moisture, dust, chemicals, and even extreme temperature variations, making them a good choice for both indoor and outdoor applications.

How are custom silicone rubber gaskets manufactured?

Data Graphic’s manufacturing of custom silicone rubber gaskets employs a die-cutting processes. Die-cutting involves cutting gaskets from pre-made silicone rubber sheets using precision equipment.

Can silicone rubber gaskets effectively seal against moisture and water penetration/ingress?

For sure. In fact, it’s often an ideal use for these gaskets. Silicone rubber gaskets are known for their excellent water and moisture resistance. They can create reliable seals that prevent water ingress, making them suitable for applications in wet environments, outdoor settings, and industries where water resistance is a top priority.

How long do silicone rubber gaskets last before they must be replaced?

The useful life of silicone rubber gaskets varies widely based on factors such as the gasket’s formulation, application conditions, usage and maintenance. Generally, silicone rubber gaskets exhibit good durability and longevity due to their resistance to weathering, UV exposure, and temperature fluctuations. With proper material selection and design, silicone rubber gaskets can maintain their sealing performance over several years. To maximize the life of these gaskets, we recommend regular inspections and maintenance.

Qualified to Deliver to Your Exact Specifications