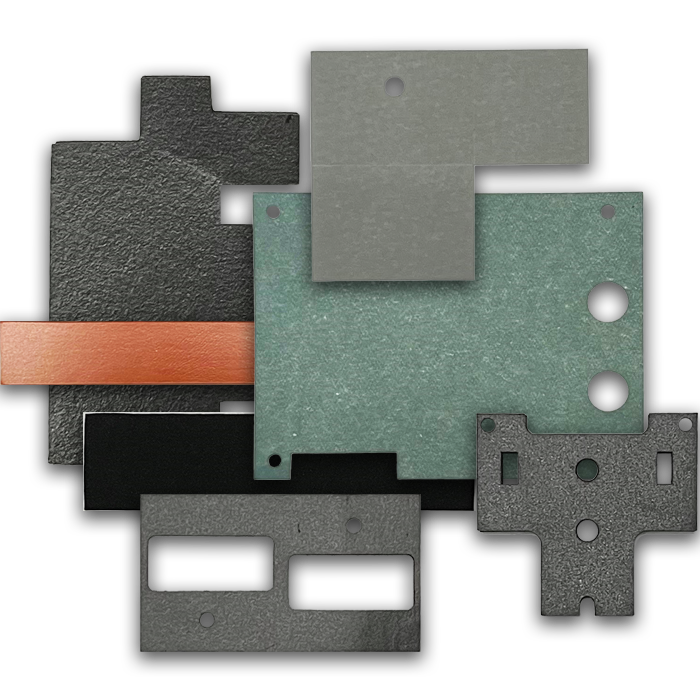

Polyurethane Foam: Exceptional Sealing Solutions for Diverse Applications

When evaluating polyurethane versus rubber for your gaskets, polyurethane is the clear winner. Polyurethane is unique because it provides the elasticity of rubber, but offers the strength and durability of metal. You might also hear it referred to as “urethane.” Gaskets created from Polyurethane are tough and abrasion-resistant (have the ability to resist wear caused by friction). They can outperform their plastic, rubber and steel counterparts.

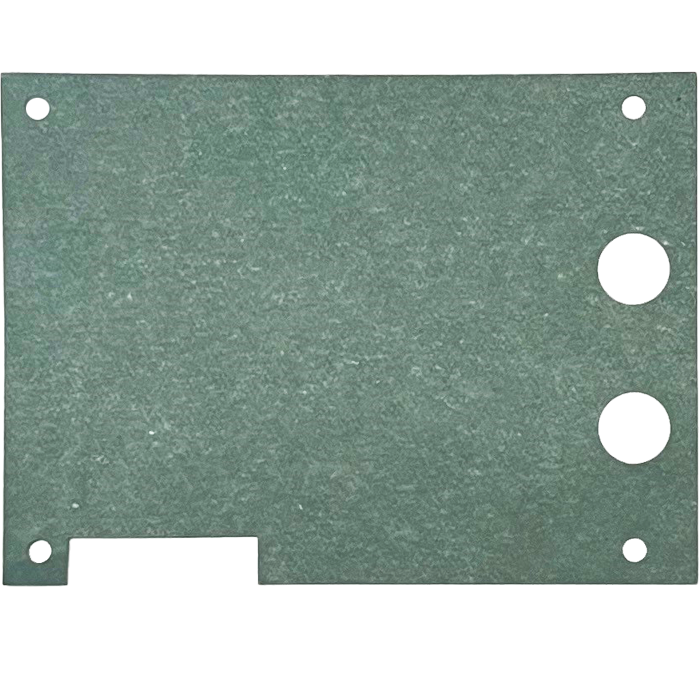

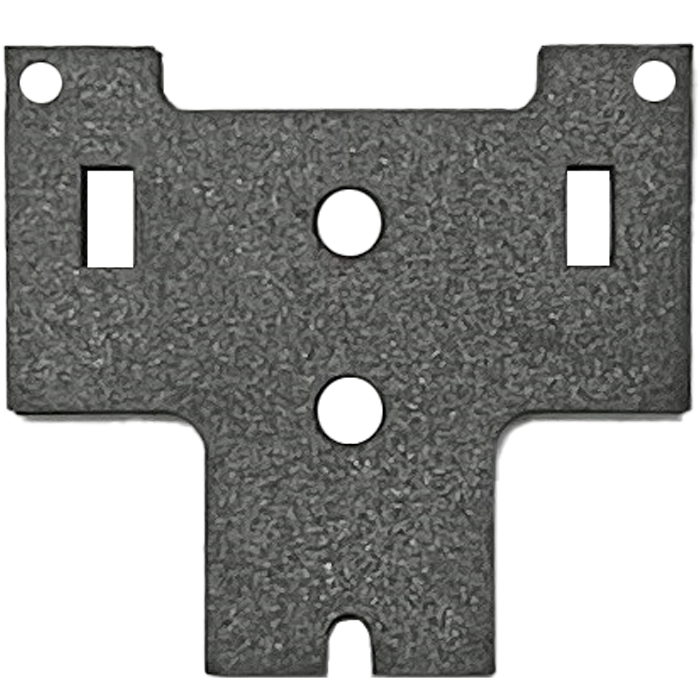

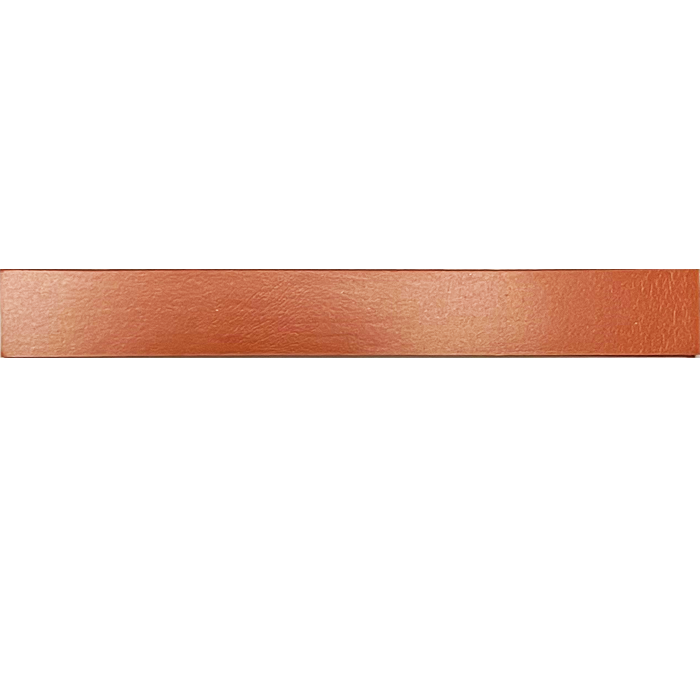

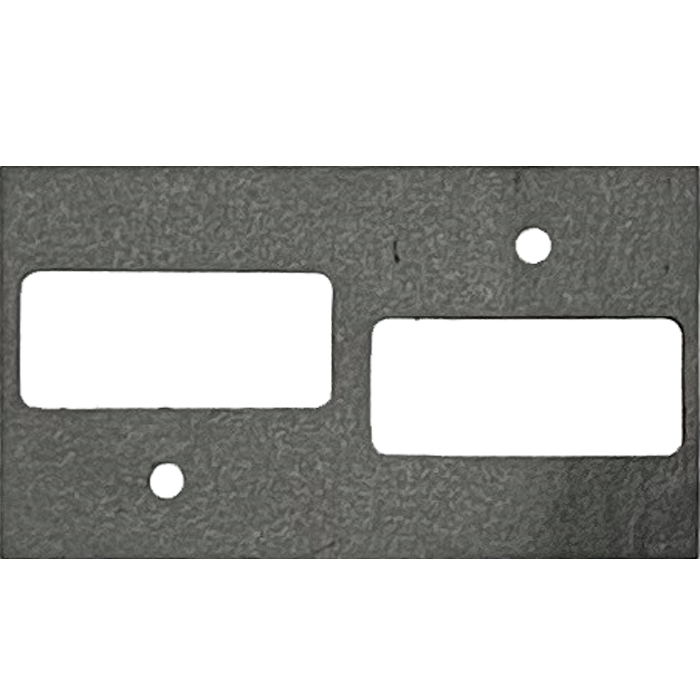

Polyurethane gaskets are resistant to many environmental elements like heat, acid, oil (and other chemicals), abrasion and changing weather conditions (wet, damp, dry, sunlight). It is more resistant to cuts or cracks and is immune to ozone and oxygen. It is also proven to have higher load bearing capacity (high-stress or high-load). A polyurethane gasket will create a seal between two parts. It stops leaking out of or into the pieces it’s joining. Our polyurethane gaskets come in a variety of designs, sizes, and thicknesses. We use high quality Poron® polyurethane and can offer it with or without adhesive.

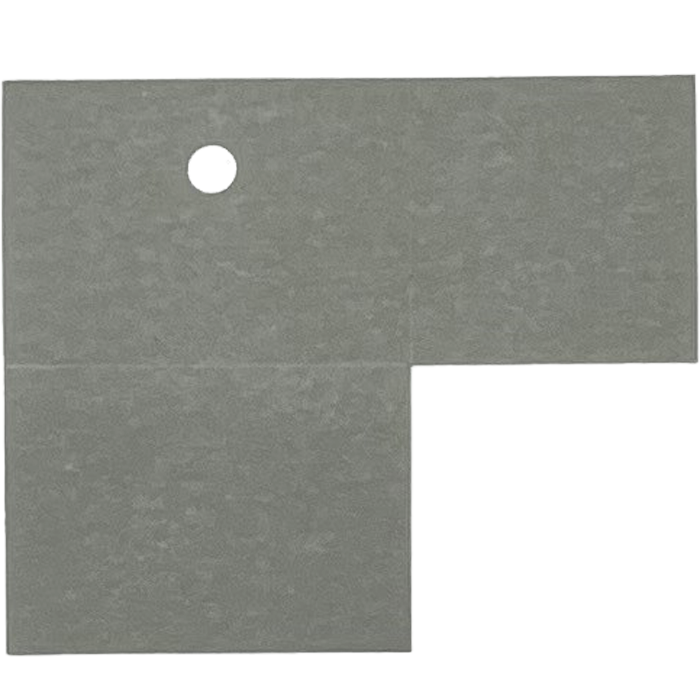

Regardless of your application, we have a completely custom die cut solution that will meet your strict requirements and specifications. We can tailor make your polyurethane gaskets to the specifications of your industry (or environment). Our die cutting equipment allows us to create the custom solution other companies can’t match. Almost every detail can be customized, including the sheet size, durometer, and thickness. Also, available in a wide range of colors.

Some of the more common applications for polyurethane gaskets are:

- wear pads

- electrical equipment

- machine mounts

- vibration damping

- shock absorption

It is the ideal choice for engineers searching for long term high load and high stress applications.

Data Graphics can create your polyurethane gaskets using a variety of methods. Our 25,000-square-foot facility in Mount Dora contains the most modern die-cut and printing equipment available on the market today.

The average turnaround on a job can take seven to ten business days after the design has been approved by the client.

Get a Quote today for your Polyurethane Gaskets!

Polyurethane Foam FAQs

What are the main benefits of using polyurethane foam gaskets?

Polyurethane foam gaskets offer several advantages. Their flexible nature allows them to conform to uneven surfaces, ensuring reliable sealing even in challenging environments. Their resilience contributes to durability and resistance against wear, tear, and chemical exposure. In addition, polyurethane foam can be manufactured with varying levels of hardness, offering customized levels of compression and insulation. This makes them ideal for applications that require both sealing and cushioning properties.

What things should I consider when designing a polyurethane foam gasket for my application?

When designing a foam gasket, factors like application requirements, operating conditions, and desired properties are crucial. Also, be sure to consider the temperature range, chemical exposure, compression needs, and expected wear. The gasket’s geometry and dimensions should also match the sealing surface. Not sure about the most appropriate design decisions to support your application? No problem. We’re here to help!

Are polyurethane foam gaskets resistant to chemicals?

Polyurethane foam gaskets CAN demonstrate varying levels of chemical resistance depending on the specific formulation and additives used in their production. Some formulations are more resistant to certain chemicals, oils, and solvents than others. If your application involves exposure to harsh chemicals, it’s essential to communicate these details to the team at Data Graphics. We can guide you in selecting a foam with the appropriate chemical resistance properties for your needs.

Qualified to Deliver to Your Exact Specifications