Custom Machine Data Plates: Ensuring Compliance and Professional Identification

Custom machine data plates may seem like small details, but they are essential to industries like aerospace, manufacturing, and military, serving as a critical component for equipment compliance, safety, and efficiency. For procurement managers, engineers, and technical experts who prioritize precision and reliability, understanding the role these data plates play is paramount to operational success. Not only do they serve as key compliance tools, but they also provide vital specifications that help keep machinery functioning optimally.

In this blog, we will dive into the critical role of custom machine data plates, the essential information they contain, and the differences between laser etching and engraving for customization. We’ll explore how high-quality, customized data plates contribute to meeting regulatory requirements, improving safety protocols, and streamlining equipment maintenance.

What Are Custom Machine Data Plates?

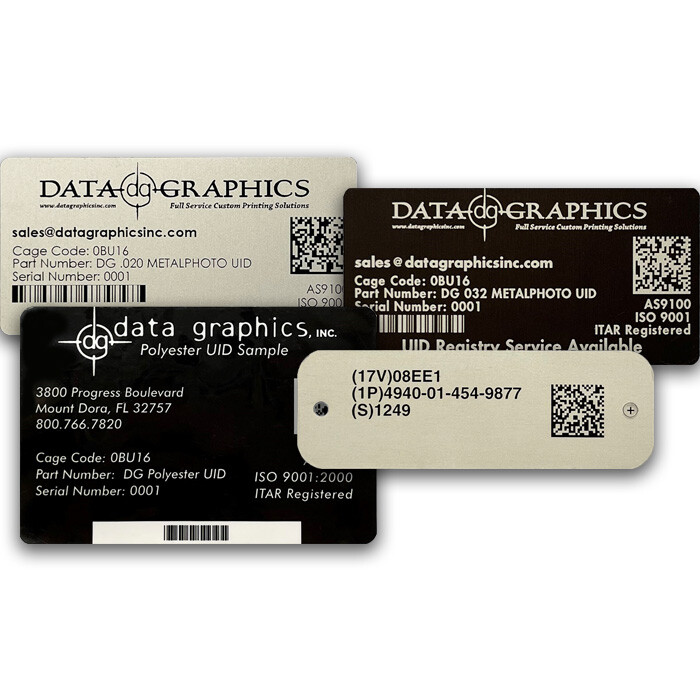

Custom machine data plates are durable metal tags or plates affixed to machinery and equipment, providing important specifications and compliance details. These plates typically display essential information such as serial numbers, model numbers, equipment specifications, and regulatory certifications. In industries like aerospace, manufacturing, military, medical, and telecommunications, these data plates not only identify equipment but also ensure it adheres to safety and operational regulations.

These plates come in various shapes, sizes, and materials, allowing for full customization to meet the specific needs of different industries. Made from tough, resilient materials like anodized aluminum, stainless steel, and brass, they are designed to withstand extreme environments, including high temperatures, moisture, chemical exposure, and physical wear, ensuring that the crucial data they hold remains legible and intact throughout the equipment’s lifespan.

The Role of Data Plates in Compliance

Custom machine data plates are an essential part of maintaining compliance with industry-specific safety and regulatory standards. In highly regulated industries like manufacturing, aerospace, and military, data plates help ensure that equipment meets the necessary safety requirements, reducing the risk of accidents and downtime.

Ensuring Safety Compliance

Safety compliance is a top priority in industries that handle complex machinery. By including vital information such as safety ratings, power specifications, and compliance marks, data plates help companies demonstrate their commitment to providing safe equipment. Below are key certifications that Data Graphics Inc. maintains and can incorporate on data plates:

AS9100:2016 Rev D: This aerospace quality management system certification demonstrates that equipment manufacturing meets the rigorous standards required by the aerospace and defense industries. This certification is essential for companies supplying equipment to aerospace manufacturers and defense contractors.

ISO9001:2015: This international quality management standard ensures that manufacturing processes consistently meet customer and regulatory requirements. ISO certification demonstrates organizational commitment to quality control and continuous improvement.

UL Certification: The Underwriters Laboratories (UL) mark indicates that equipment has passed stringent safety tests, ensuring it meets U.S. standards for electrical and fire safety. Data Graphics Inc. holds UL 969 and PGDQ2 special designations, making us one of the most widely certified nameplate manufacturers in America. This certification is vital for businesses that need to prove their equipment’s reliability and safety to customers and regulatory bodies.

ITAR Compliance: For equipment in defense and military applications, International Traffic in Arms Regulations (ITAR) compliance is mandatory. Data plates on ITAR-compliant equipment must meet strict manufacturing and security standards.

MIL-STD-130 n: This military standard specifies requirements for the identification marking of U.S. Department of Defense property. Data Graphics Inc. has manufactured millions of DoD-compliant labels and nameplates, ensuring proper military asset tracking and identification.

By including these important compliance marks on data plates, businesses not only adhere to legal requirements but also foster trust among customers, employees, and regulators, demonstrating that their equipment is both safe and compliant.

Assisting in Equipment Tracking

In addition to helping with compliance, custom machine data plates are instrumental in tracking the equipment’s lifecycle. Serial numbers, model numbers, and manufacturer details provide the necessary information for managing maintenance, repairs, and warranty claims. For procurement managers and engineers, data plates are a vital tool for efficient equipment management.

The use of serial numbers allows businesses to trace the service history of equipment, ensuring that the right maintenance and replacement parts have been used. This contributes to improving the operational life of machinery and helps streamline service schedules. In industries like aerospace and military, where safety is a top priority, having detailed tracking information ensures that the equipment is always maintained according to the manufacturer’s specifications and legal requirements.

Key Information Featured on Data Plates

The most crucial function of custom machine data plates is to provide critical information for both identification and compliance. The data plates typically feature the following essential details:

1. Equipment Specifications

Custom machine data plates contain important technical information about the equipment, including:

Power Ratings: These include the voltage, current, and frequency requirements of the equipment, ensuring compatibility with its power source and preventing issues related to electrical supply mismatches.

Physical Dimensions: Information about the size and weight of the equipment is crucial for proper installation, operation, and space management.

Model Numbers and Serial Numbers: These unique identifiers allow businesses to track equipment for repairs, warranties, and service history. Serial numbers enable improved inventory management, asset visibility, maintenance tracking, and compliance with government regulations or industry standards.

Manufacturing Date: The date the equipment was manufactured helps determine its age, warranty period, and service requirements, ensuring that maintenance schedules are adhered to accurately.

By including all this information on the equipment’s data plate, businesses can ensure accurate maintenance, reduce downtime, and optimize operational efficiency.

2. Compliance Marks

Displaying compliance marks on the data plate is essential for ensuring that the equipment meets specific safety and performance standards. These certifications demonstrate that the equipment adheres to required regulatory standards, enhancing the trust and credibility of the product.

Common compliance marks include:

UL (Underwriters Laboratories): Ensures the equipment meets U.S. safety standards for electrical safety.

ISO Certifications: Validate compliance with international standards for quality management, environmental sustainability, and safety practices.

AS9100: Confirms adherence to aerospace industry quality management standards.

MIL-STD-130 n: Validates compliance with Department of Defense identification marking requirements.

These marks help businesses stay compliant with regulatory requirements and give their customers confidence in the safety and reliability of their equipment.

Laser Etching vs. Engraving: Which Is Right for Your Data Plate?

When customizing your data plates, you have the option to choose between laser etching and engraving, depending on your specific needs. Both methods provide durable, high-quality results but are suited to different applications.

Laser Etching

Laser etching involves using a laser to create permanent markings on the material’s surface. This process provides exceptional precision and is ideal for intricate designs, variable data, and detailed graphics.

Advantages of Laser Etching:

High precision: Allows for fine details, small fonts, logos, and graphics with exceptional clarity and accuracy.

Permanent marking: Highly resistant to fading, scratching, and wear, ensuring long-term legibility.

Variable data capability: Perfect for serialized information, barcodes, QR codes, and unique identifiers required for tracking purposes.

Versatile applications: Suitable for product branding, identification tags, control panels, equipment labels, and functional markings.

Engraving

Engraving is a permanent, durable process where information is mechanically carved into the surface of the material. This method is ideal for equipment exposed to the harshest environments, ensuring the information remains legible even in extreme conditions.

Advantages of Engraving:

Long-lasting durability: Resists wear and tear in extremely harsh conditions, maintaining legibility over extended periods even with physical abrasion.

Deep marking: Provides maximum visibility and tactile feel, making it easy to read even in low-light or dirty environments.

Resistance to harsh conditions: Engraving ensures that the information remains intact in extreme conditions like high temperatures, chemical exposure, or rough physical conditions.

High-visibility: Provides a professional and easy-to-read appearance, even in high-traffic industrial environments.

Choosing between laser etching and engraving depends on your specific application and environmental requirements. Both methods provide high-quality results but serve different use cases based on durability needs and design complexity.

Metalphoto®: The Premium Solution

For the most demanding applications, Data Graphics Inc. offers Metalphoto® nameplates, the highest resolution metallic print solution available. As a Metalphoto Certified Converter, Data Graphics produces nameplates that meet MIL-STD-130 n standards.

The Metalphoto process embeds high-resolution graphics and text into anodized aluminum, creating a durable, long-lasting solution. The silver halide image is permanently sealed within the anodic layer, making it nearly impervious to harsh environmental elements including extreme temperatures, UV radiation, chemical exposure, and physical abrasion.

Why Choose Data Graphics Inc. for Custom Machine Data Plates?

At Data Graphics Inc., we specialize in crafting custom machine data plates designed to meet the highest industry standards. Here’s why we are the best choice for your custom data plate needs:

Proven Track Record: We are winners of the Platinum Premier Supplier Award from Rockwell Collins and the prestigious Gold Supplier Award from Boeing. Our client list includes Fortune 500 companies like Samsung,Siemens, and GE. More than 80% of customers return for repeat orders.

Uncompromising Quality: We recently completed a $1 million upgrade of our facilities and machinery, including the addition of a new Hewlett Packard Indigo 5600 Digital Press. We maintain critical quality certifications including UL (969 and PGDQ2), AS9100:2016 Rev D, ISO9001:2015, Metalphoto, and ITAR Compliance—making us one of the most widely certified nameplate manufacturers in America.

On-Time Delivery: We complete 60% of our custom printed labels ahead of schedule. Our meticulously organized facility and well-maintained equipment ensure faster production without compromising quality.

Customization: We offer fully customizable data plates with laser etching, engraving, and Metalphoto® options, tailored to your specific requirements and environmental conditions.

Compliance Assurance: Every data plate we create is built to meet relevant industry standards, including MIL-STD-130 n, AS9100, ISO9001, UL, and ITAR requirements, helping you stay fully compliant with regulations.

Durability: Whether you need data plates for harsh military environments, aerospace applications, or standard industrial use, we deliver durable, high-quality solutions using materials like anodized aluminum, stainless steel, and brass.

Partnering with Data Graphics Inc. ensures that your equipment is properly identified, compliant with regulations, and equipped with data plates that stand the test of time.

Discover Which Data Plate Solution Is Right for You

Custom machine data plates are a critical component in ensuring equipment compliance, operational safety, and efficient maintenance. Whether you choose laser etching for precision and detail, engraving for maximum durability, or Metalphoto® for the highest-resolution permanent solution, these plates provide essential information that helps businesses meet legal requirements, enhance safety protocols, and improve equipment tracking.

At Data Graphics Inc., we offer top-quality custom machine data plates that cater to the needs of industries such as aerospace, military, medical, telecommunications, and manufacturing. With our focus on precision, compliance, and durability—backed by prestigious awards from Boeing and Rockwell Collins—we are your trusted partner for ensuring that your equipment remains safe, operational, and properly identified.

Contact Data Graphics Inc. today to discuss your custom machine data plate needs and discover why America’s leading companies trust us for their critical identification requirements.