Nameplate Failure: 5 Spec Errors to Avoid

1. Material Mismatches for Harsh Environments

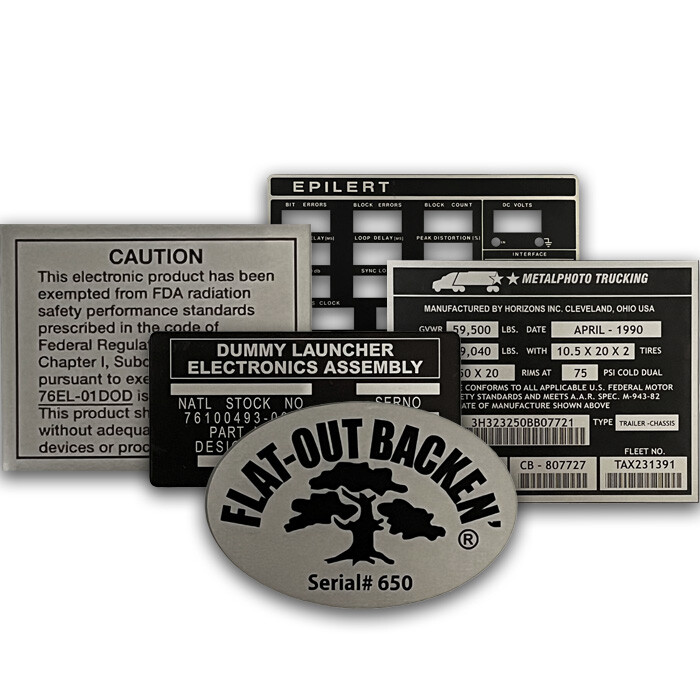

The most critical consideration in selecting nameplate specifications is choosing the appropriate material that can withstand the specific environment in which the nameplate will be used. Whether the nameplate will be exposed to extreme temperatures, outdoor conditions, chemicals, or mechanical stress, the material must be robust enough to endure the environment without degrading.

For example, if you’re using nameplates in an outdoor environment, the material needs to resist UV rays and environmental elements such as rain, snow, and dust. Industrial nameplates used in machinery or outdoor applications are frequently exposed to the sun, meaning UV degradation and fading are common problems. Nameplates made from basic materials like uncoated aluminum or plastic will degrade quickly under these conditions, resulting in a need for costly replacements.

How to Avoid This Mistake:

Always assess the specific environmental conditions your nameplate will face. If the application involves exposure to chemicals, high humidity, or extreme temperatures, ensure the material selected is resistant to those factors. Metalphoto nameplates are a great choice for industries requiring long-term durability in harsh environments, offering protection against fading, abrasion, and corrosion.

Metalphoto nameplates are especially beneficial in industrial applications where harsh environmental conditions are a concern. They are engineered to handle a range of demanding settings, making them an ideal solution for industries like aerospace, military, and chemical processing, where precision and longevity are critical. Our Metalphoto® process embeds images into photosensitive anodized aluminum, creating a 25-year exposure certified solution that remains legible and effective for the long term, without the need for costly replacements or maintenance.

2. Adhesive Failures: A Hidden Issue

While nameplates can be attached to various surfaces through methods like mechanical fasteners or adhesives, adhesive failure is one of the most common reasons for nameplate detachment. Improper adhesive choices can lead to nameplates peeling off or losing their effectiveness in high-stress environments.

Certain nameplate applications, such as those used in the aerospace or automotive industries, demand adhesives that can withstand extreme heat, moisture, and other environmental factors. For example, adhesive failure in nameplates used in heavy equipment can cause them to detach during operation, leading to loss of critical information and even safety hazards.

How to Avoid This Mistake:

Ensure that the adhesive selected is designed specifically for the material of the nameplate and the surface it will adhere to. For Metalphoto nameplates, specialized adhesives that can withstand the environmental conditions, such as temperature, chemicals, and moisture, should be selected. Consult with the manufacturer or supplier to ensure you’re using the right adhesive for long-term durability.

The adhesive used to attach nameplates should also meet the specific requirements of the surface it adheres to. Whether for metal, plastic, or other materials, the adhesive should create a strong bond that resists wear and tear over time. When working with industries that have stringent requirements, such as aerospace or military, where Data Graphics Inc. holds AS9100:2016 Rev D certification and ITAR compliance, it’s essential to choose adhesives that provide a permanent bond that won’t degrade under exposure to chemicals, high temperatures, or moisture. For industries where precision is paramount, even a minor adhesive failure could lead to non-compliance or safety risks.

3. Inadequate UV and Chemical Testing

One of the most common errors in nameplate specification is failing to conduct adequate testing for UV resistance and chemical exposure. In environments where nameplates are exposed to sunlight, UV degradation can cause fading, which reduces the legibility of important information. Likewise, in industries like chemical processing or oil refining, nameplates must be able to resist exposure to various harsh chemicals.

When these factors are not considered during the nameplate selection process, you may end up with nameplates that are only effective for a short time. For instance, Metalphoto nameplates are made with high-quality imaging processes that allow them to withstand prolonged UV exposure, ensuring that the information remains visible and legible throughout their service life.

How to Avoid This Mistake:

Always request UV and chemical testing as part of the specification process. If you’re in an environment where the nameplate will be exposed to chemicals or sunlight for extended periods, make sure the nameplate material is tested to ensure it will endure these conditions. Metalphoto nameplates, for example, undergo extensive testing for UV light and chemical resistance, making them ideal for applications that demand long-term durability. Our products meet rigorous standards, including MIL-STD-130 n, ASTM B209-10, and UL 969 compliance.

For industries where time is of the essence, such as aerospace and military applications, nameplates that fail to meet UV and chemical testing requirements could result in compliance issues or costly downtimes. UV and chemical testing help ensure that the nameplates continue to meet industry standards and remain functional throughout their service life, offering peace of mind to your business.

4. Incorrect Printing Methods: Choose the Right Technique

The printing method used to mark the nameplates plays a crucial role in their durability. Poor printing techniques can result in the fading, smudging, or peeling of information, rendering the nameplate ineffective and non-compliant with regulations.

For example, traditional inkjet printing may not provide the long-lasting results required for industrial nameplates that are exposed to high temperatures or chemicals. In such cases, the information may start to fade or blur, which could pose safety risks in critical applications. Similarly, laser etching or engraving might be too shallow and may wear down over time.

How to Avoid This Mistake:

Always select a printing method that suits the application and environmental conditions. For high-performance applications that require long-term durability, opt for Metalphoto nameplates, which use photographic imaging to ensure the longevity of printed information. Consult with your supplier to determine the best printing method for your specific application.

In industries like aerospace, military, and manufacturing, where accuracy and compliance are key, the printing technique should align with the rigorous standards required for long-term performance. Metalphoto nameplates use a proprietary process to embed images into the metal through photosensitive anodized aluminum technology. The silver halide image is permanently sealed within the anodic layer, ensuring that the information remains permanently etched into the material, regardless of environmental conditions. This method guarantees that nameplates will endure harsh conditions without the risk of fading, smudging, or deterioration, a capability that has made Data Graphics Inc. a trusted supplier to companies like Boeing, Rockwell Collins, and Lockheed Martin.

5. Failing to Meet Regulatory Compliance

In many industries, nameplates must meet specific regulatory requirements for safety, identification, and compliance. Failure to meet these standards can result in significant penalties, as well as safety risks. Regulatory bodies like the FAA (Federal Aviation Administration) for the aerospace industry or OSHA (Occupational Safety and Health Administration) for chemical plants require that nameplates meet strict standards for material quality, durability, and legibility.

For example, nameplates used in industrial equipment must often include specific safety warnings, operating instructions, and compliance information. If these nameplates are not produced to the correct standards, the equipment may not be compliant with federal regulations, resulting in costly fines or legal issues.

How to Avoid This Mistake:

Always ensure that your nameplates meet the regulatory standards for your industry. Work with a reputable supplier, like Data Graphics, Inc., that understands the regulatory requirements and can ensure that your nameplates are manufactured to meet all compliance standards. Whether it’s meeting aerospace, chemical, or safety industry standards, we help you create nameplates that adhere to all necessary regulations.

Meeting regulatory standards is not just about compliance; it’s also about maintaining the safety and integrity of your operations. Industries like aerospace and military have strict guidelines for nameplate specifications to ensure that equipment operates safely and efficiently. Data Graphics Inc. holds critical certifications, including AS9100:2016 Rev D (aerospace quality management), ISO9001:2015 (quality management), UL certification (including UL 969 and PGDQ2 designations), ITAR compliance, and our prestigious Metalphoto® Certified Converter status since 2016. Partnering with Data Graphics, Inc. ensures that all regulatory requirements are met, helping you avoid potential fines or legal issues.

Conclusion: Partner with Data Graphics, Inc. for the Best Nameplate Solutions

At Data Graphics, Inc., we understand the importance of selecting the right nameplate specifications for your industrial applications. Since our founding in 1984, we have grown into one of America’s most distinguished industrial printing companies, with a proven track record serving Fortune 500 companies across the medical, aerospace, military, OEM, and telecommunications industries. As one of only the top 10 Metalphoto® Certified Converters in the nation since 2016, we bring unmatched expertise in producing nameplates that meet the most demanding specifications.

Our 25,000-square-foot production facility in Mount Dora, Florida, underwent a $1 million renovation in 2013, ensuring we have the capacity and technology to deliver exceptional quality. We maintain comprehensive certifications, including AS9100:2016 Rev D, ISO9001:2015, UL (969 and PGDQ2), ITAR compliance, and Metalphoto® certification. Our commitment to excellence has earned us prestigious recognition, including the Boeing Gold Supplier Award, Rockwell Collins Platinum Premier Supplier Award, and the 2022 Outstanding Small Business Supplier to Lockheed Martin.

Don’t risk nameplate failure due to poor material choices, incorrect adhesives, or inadequate testing. Trust the experts at Data Graphics, Inc. to provide you with the highest quality nameplates that meet your unique requirements and stand the test of time.

Contact us today to learn more about how we can help you choose the right nameplate specifications for your needs and avoid costly errors that could result in failure, non-compliance, and replacements.