What Makes a Metal Nameplate Durable? Materials, Finishes, and Applications Explained

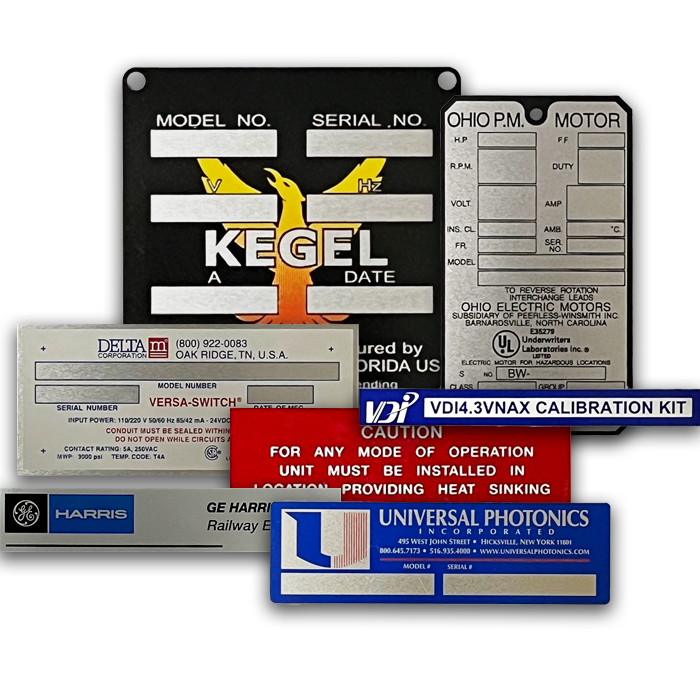

In industrial and military environments, durability is paramount. Whether used for identification, branding, or safety, metal nameplates must ensure information remains legible and intact even under the harshest conditions. For procurement managers and technical experts in aerospace, military, and medical industries, selecting the right metal nameplate goes beyond aesthetics—it’s about precision, reliability, and long-term performance. This article explores the materials, finishes, and techniques that contribute to the durability of metal nameplates, focusing on options like aluminum, stainless steel, and anodized finishes. We will also discuss engraving, etching, and screen printing methods, which enhance their resilience and legibility.

Materials Used for Durable Metal Nameplates

The durability of a metal nameplate is heavily influenced by the material chosen for its construction. Different materials offer unique advantages that cater to various industrial and military applications, ensuring that your nameplate remains functional in the most demanding environments.

Aluminum Nameplates

Aluminum is one of the most popular materials used for manufacturing metal nameplates due to its lightweight, corrosion-resistant properties. This material is highly durable, especially in outdoor environments. Aluminum nameplates are often used in applications where weight is a key consideration, such as on vehicles, machinery, and equipment.

Aluminum is also renowned for its ease of engraving and etching, which allows for intricate designs and precise markings. Additionally, the anodization process adds an extra layer of protection, making the nameplate even more resilient to the elements, including UV rays, rain, and chemicals. This electrochemical process thickens the natural oxide layer of aluminum, improving its resistance to wear and corrosion.

For industries where reliability is critical, anodized aluminum nameplates ensure that information remains intact for years, even in extreme conditions.

Stainless Steel Nameplates

For environments where heavy-duty durability is required, stainless steel is an ideal choice. Known for its strength and resistance to corrosion, scratches, and other forms of physical damage, stainless steel is perfect for industrial settings, power plants, and military applications. Stainless steel nameplates can withstand high temperatures, making them suitable for environments with intense heat.

In addition to its toughness, stainless steel offers an aesthetically sleek appearance. Polished or brushed finishes can be applied, enhancing the nameplate’s visual appeal while maintaining functionality. Stainless steel nameplates also ensure that your branding or identification information remains legible, even under the harshest conditions.

Brass and Bronze Nameplates

Although less commonly used than aluminum or stainless steel, brass and bronze offer an elegant and durable solution for specific applications. These metals are highly resistant to corrosion, making them ideal for environments that require a more decorative, traditional appearance, such as high-end residential or luxury settings, museums, and memorials.

Brass and bronze nameplates develop a beautiful patina over time, adding a distinct character and aesthetic value. These metals provide a unique balance of style and functionality, offering a durable option for environments where both visual appeal and resilience are essential.

Finishes that Enhance Durability

The finish applied to a metal nameplate is just as important as the material. Finishes not only improve the nameplate’s appearance but also provide additional protection against the elements, ensuring long-lasting performance.

Anodized Finishes

An anodized finish is one of the most effective methods for protecting aluminum nameplates from corrosion and wear. The anodizing process thickens the natural oxide layer on the metal surface, creating a hard, durable surface that resists scratches, fading, and tarnishing.

Anodized aluminum can be dyed in a variety of colors, offering both functional and aesthetic benefits. This finish is ideal for industries where both functionality and customization are crucial, such as in signage, equipment tags, and military identification plates. The anodized finish also provides enhanced precision and longevity, ensuring the nameplate remains legible and visually appealing for years.

Powder Coating

Powder coating is a durable finish for metal nameplates, especially in environments exposed to UV rays, corrosion, and chemicals. This process involves applying a dry powder to the metal surface, which is then heated to form a tough, resilient coating. The result is a smooth, uniform finish that resists scratching, fading, and chipping.

Metal nameplates with powder-coated finishes are frequently used in industrial settings where exposure to harsh chemicals or extreme temperatures is common. This finish provides extra protection, ensuring the nameplate’s long-term performance and visual integrity.

Brushed and Polished Finishes

Brushed and polished finishes are often applied to stainless steel and brass nameplates, adding both aesthetic value and durability. A brushed finish gives the metal a textured appearance, which helps hide scratches and wear. This is particularly useful for nameplates placed in high-traffic areas or environments where the nameplate is subject to frequent contact.

A polished finish offers a sleek, shiny appearance that reflects light. While it requires more maintenance to maintain its shine, it provides an elegant look suitable for luxury applications. Both finishes enhance the precision and professional appearance of nameplates used in demanding industrial or military environments.

Engraving, Etching, MetalPhoto, and Screen Printing: Techniques that Enhance Durability

The technique used to create the text and graphics on a metal nameplate is just as crucial as the material and finish. The method chosen impacts the nameplate’s legibility, precision, and overall durability.

Engraving

Engraving is one of the most durable methods for creating permanent markings on metal nameplates. This process uses a rotary tool to etch the text or design directly into the metal surface. Engraving is particularly effective for materials like aluminum and stainless steel, ensuring that the information remains legible for years—even in extreme environments.

Engraving is ideal for applications such as industrial equipment tags, military identification plates, and high-visibility signage, where long-term legibility and precision are critical.

Etching

Etching is another technique used to create detailed designs or text on metal nameplates. A chemical solution is applied to the metal, which reacts with the material to create a permanent mark. Etching is perfect for applications requiring intricate details, such as product identification or serial numbers.

Etching works well on both stainless steel and aluminum, and can be combined with anodized finishes for added contrast and durability. This technique ensures that the nameplate’s information remains intact and legible over time.

MetalPhoto/Photosensitive Process

For applications demanding ultimate durability, the MetalPhoto process represents the gold standard in permanent marking technology. This advanced photosensitive technique creates markings that are virtually indestructible, making it the preferred choice for critical aerospace, military, and medical applications.

The MetalPhoto process uses a digital-capable machine to develop images on the inner layer of photosensitive anodized aluminum. The silver halide image becomes permanently sealed within the anodic layer, making it nearly impervious to the elements. Unlike surface-applied markings, these become an integral part of the metal itself.

This technology offers extraordinary resistance to extreme temperatures, salt spray, chemicals, UV radiation, abrasion, cleaners, lubricants, and fuels. The photographic process allows for high-resolution imaging, enabling inclusion of serial numbers, barcodes, QR codes, and intricate graphics that maintain exceptional clarity and contrast over decades of exposure.

MetalPhoto excels in applications requiring permanent traceability and regulatory compliance. The process meets MIL-STD-130N and ASTM B209-10 standards, making it ideal for military and aerospace procurement specifications where asset identification must remain scannable throughout the equipment’s entire lifecycle. With 25-year exposure certification, this process ensures critical information remains intact when failure is not an option.

Screen Printing

Screen printing is a versatile technique used to apply color to metal nameplates. Ink is pressed through a mesh screen onto the metal surface, resulting in bold, vibrant colors that enhance legibility and visibility. This method is commonly used for logos, brand names, or large text.

While screen printing is effective for creating eye-catching designs, it is less durable than engraving or etching. The ink can wear off over time, particularly in outdoor environments. However, when used in combination with finishes like powder coating, screen printing can offer increased resilience and longevity.

Choosing the Right Metal Nameplate for Your Needs

Selecting the right metal nameplate depends on several factors, including environmental conditions, required durability, and aesthetic preferences. For outdoor applications, aluminum with anodized finishes or stainless steel are excellent choices, offering superior resistance to weathering, corrosion, and physical damage.

For indoor environments or applications that require a more decorative appearance, brass and bronze nameplates offer both durability and style. When customization is a priority, engraving or etching on aluminum or stainless steel provides a solution that guarantees long-term legibility and precise design details.

Conclusion

Metal nameplates are essential components in a variety of industrial, military, and commercial applications. The materials, finishes, and engraving techniques used to create these nameplates determine their durability and performance. By understanding the available options—such as choosing the right material like aluminum or stainless steel, or opting for finishes like anodizing or powder coating—you can select a metal nameplate that meets your durability needs and withstands even the harshest environments.

Data Graphics, Inc. offers precision-engineered nameplates, combining high-quality materials, finishes, and engraving techniques to ensure longevity and performance. Ready to experience durability you can trust? Contact us today for customized metal nameplate solutions tailored to your specific needs.