Selected as a 2022 Outstanding Small Business Supplier to Lockheed Martin and have been selected as a GROWFL Florida Companies to Watch 2023 Awardee!

Sequential Labels

Giving your product a Unique Identity

Product Identification labels are usually printed in sequential order. During the process in which they are printed, they are given an alpha numeric or numerical serial number. The serial numbers are assigned to a group of identical terms. The specific serial numbers give the product a unique identity. A few labels or nameplates have serial numbers with barcode symbols. The labels that do not have any barcode symbology can be embossed with lone serial numbers. For example, checkbook checks each receive a unique number in a sequential order

Track the Product!

Most of the time, sequential nameplates are used for inventory control, asset management production tracking, scheduling and document tracking. The aerospace, medical, telecommunications, military, and manufacturing industries are a few examples which need labels in sequential order to have better business performance. Take the manufacturing of computers for example. Businesses who produce them produce a large quantity of them that look identical. Sequential labels help accurately track these products for inventory control purposes. Another government department that uses sequential labels are libraries. To keep track of order and inventory, the Dewey Decimal System is put on the books binder helping better keep track of where book are and when they are checked out.

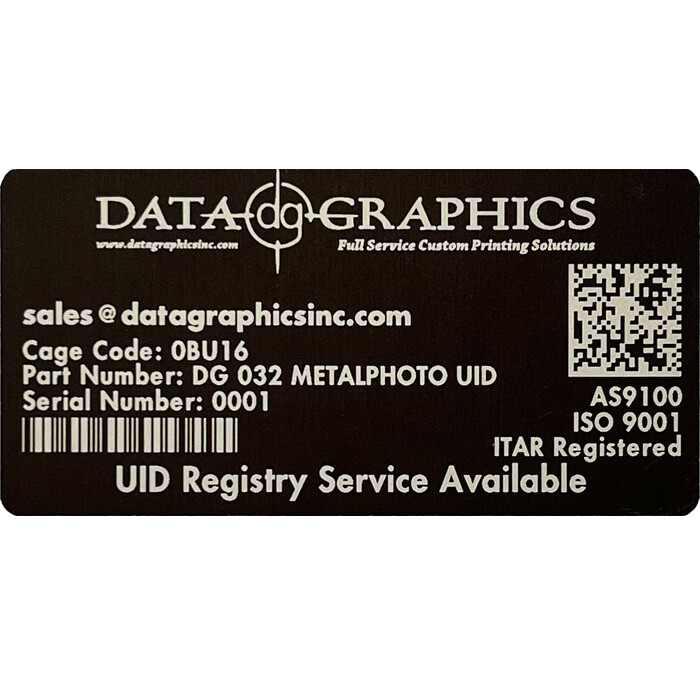

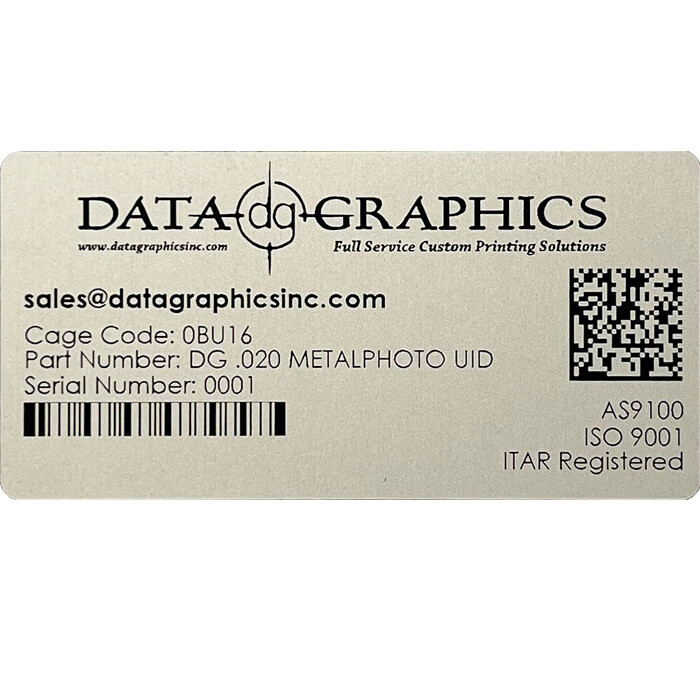

Aluminum Labels

Sequential labels can be made using a number of different materials. The most popular of these materials is anodized aluminum foil that is extremely durable. A particular company’s name, serial number, and barcode can be printed on the material leaving a highly visible image. Foil product identity labels are usually tamper evident. When the foil is taken away from the surface it was originally adhering to, it leaves a visible residue leaving a trace of tampering. Aluminum tags are perfect for indoor or outdoor applications. The asset tags can protect from harsh environments such as scuffs, heat, cleaning solvents, and most chemicals.

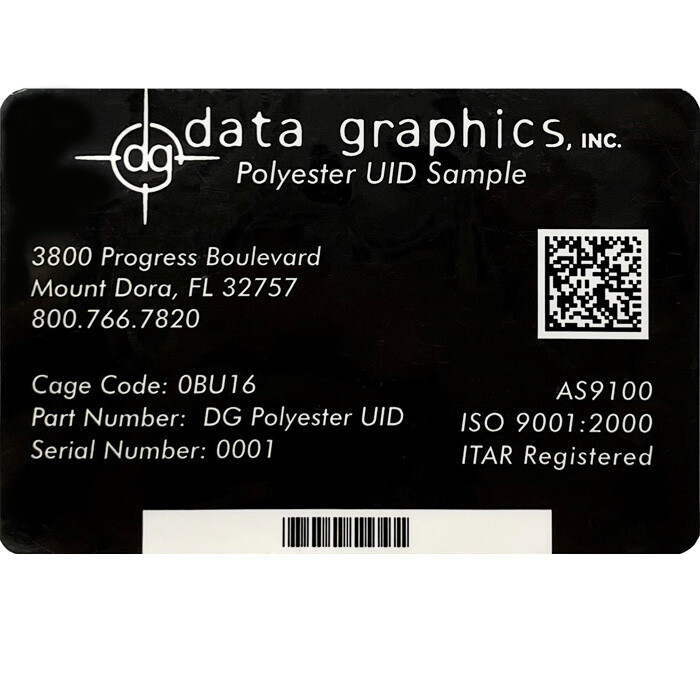

Polyester Labels

Another material option for sequential labels is polyester. This particular material is excellent for indoor applications. Applications for this material include nameplates on computers, furniture, and equipment. Polyester labels also leave a void pattern behind when peeled away. This pattern consists of the word “VOID” on the product it was adhered to. Polyester labels can be made with a laminate that ads protection from scuffs and mild chemicals.

Printing capabilities for printing sequential barcode labels include:

- Digital Printing

- Thermal transferred

- Hot stamped

- Engraved

- Serialized

Over laminates include:

- Matte

- Semi gloss

- Write on

- Protective

Contact Data graphics and talk to one of our highly trained Sales Engineers or get a quick quote today.

Sequential and Barcode Labels FAQs

What are sequential/barcode labels, and how do they work?

Sequential labels are labels with unique sequential numbers or barcodes printed on them. These numbers or codes are used for tracking, inventory management, and identification purposes. They facilitate automated data collection and information retrieval.

How are sequential or barcode labels be customized for my company’s specific needs?

Customizing sequential/barcode labels involves designing labels with specific data formats, including numbers, alphanumeric codes, or barcodes. Clients can choose label sizes, materials, adhesive types, and the printing technology best suited to their application.

What advantages do sequential/barcode labels offer?

Sequential labels (including those with barcodes) streamline inventory management, asset tracking, and data collection processes. They enhance accuracy, reduce errors, and enable efficient data retrieval, making them indispensable for supply chains, logistics, and retail operations.

Are there limitations in terms of label materials and barcode formats?

Yes. While versatile, certain barcode formats may require specific label materials to ensure accurate scanning. Additionally, barcode readability can be affected by the material’s texture, color, and finish. If you are unsure about the best materials to use for your format, contact one of our experts. Consulting with someone on our team will help determine the best combination for optimal performance.

Which industries benefit the most from sequential/barcode labels?

Industries heavily reliant on inventory management, asset tracking, and efficient data capture benefit from sequential labels. This includes retail, manufacturing, healthcare, logistics, and warehousing… but honesty, you’ll find applications for sequential labeling across hundreds of industries!

Qualified to Deliver to Your Exact Specifications