Selected as a 2022 Outstanding Small Business Supplier to Lockheed Martin and have been selected as a GROWFL Florida Companies to Watch 2023 Awardee!

Make a Bolder Statement with Nameplates from Data Graphics

When you have an important message to your employees or customers, our nameplates say it loud and clear.

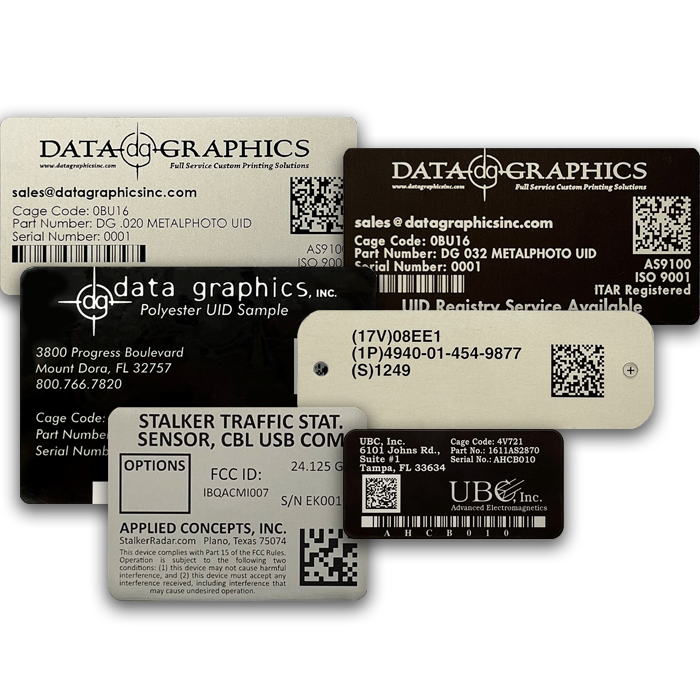

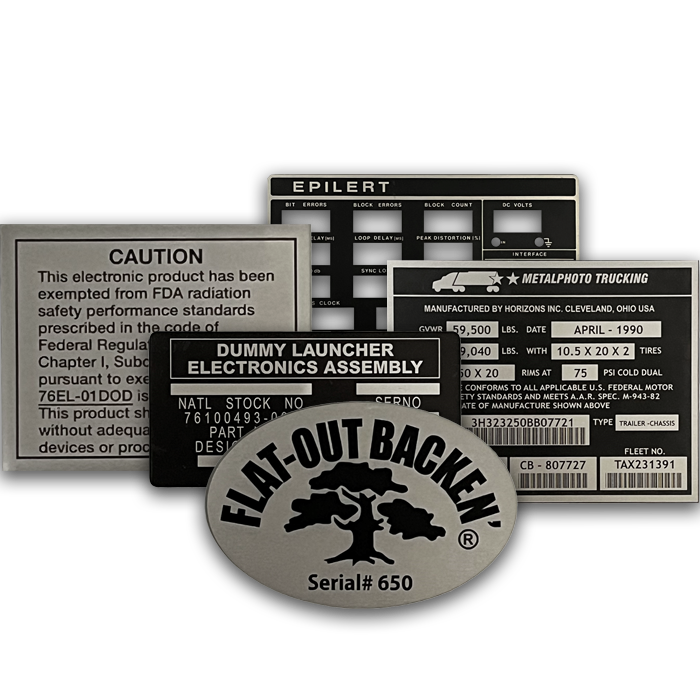

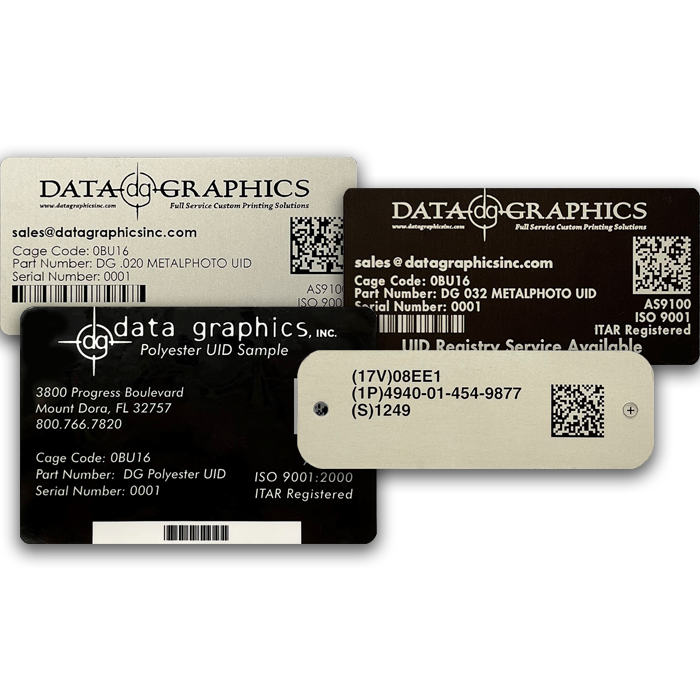

If your company is in the aerospace, military, manufacturing, medical device, industrial equipment, electronics or telecommunications industry, you can rely on our experience producing nameplates for inventory and identification purposes. The versatility of these custom nameplates allows for stamping, future etching or printing.

All of our Metalphoto® aluminum nameplates are anodized and sealed to withstand exposure to every kind of weather, extreme temperatures, sunlight, acids, salt spray, fungus and abrasives. Metalphoto® aluminum is available in a variety of finishes, thicknesses and sizes.

Should You Pick Polycarbonate, Polyester or Aluminum Nameplates?

Anodized aluminum nameplates are used for rating plates, dials and scales, templates, instructional tags, corporate identity and serial numbers. Aluminum nameplates also meet ANSI, military, as well as UL specifications. Aluminum nameplates are a favorite among our clients looking for an attractive finish in a hard, scratch-resistant material. Our cutting equipment even allows us to cut your aluminum nameplate into any shape you need, no matter the thickness.

Like aluminum, polycarbonate nameplates have superior mechanical strength, toughness and clarity. They can also survive extreme environmental conditions, such as high temperatures, chemical abrasions, and corrosion. Polycarbonates are known for their dimensional stability, optical clarity, printability and graphic design freedom. They can have a clear or textured finish. They can be embossed, die cut, lasered, selective textured and/or selective adhesive can be applied. They are also available in a wide range of thicknesses, from .005” to .118”, depending on the application.

Polyester is a versatile material that has many applications, including use in electronics, magnetic media, packaging, product identification, imaging and graphing. Both materials are great for harsh indoor and outdoor environments. Polyester nameplates meet a lot of rigorous job specs, including high tensile strength, durability, clarity, resistance to abrasion and solvents, resistance to shrinking and stretching and low electrical conduction.

You can Find Our Custom Nameplates all Over the World

The uses for custom nameplates are practically endless. We manufacture a huge variety of nameplates for a variety of purposes around the world at our state-of-the-art facility:

- Company Nameplates

- Equipment Nameplates

- Fixed Asset Labels

- Fixed Asset Tags

- Identification Nameplates

- Industrial Nameplates

- Legend Plates

- Machine Nameplates

- Metal Asset Tags

- Metalphoto ® Nameplates

- Military Nameplates

- Nameplate Signs

- Plastic Nameplates

- UID Plates

- Data Plates

- Placards

If you need assistance, our Sales Engineer can guide you through a variety of industrial nameplates printing options. Literally millions of nameplates have rolled out of our facility, including screen printed, digitally printed, UV printed, Metalphoto®, Laser Etched, CNC Engraved and anodized aluminum products.

Our state-of-the-art facility produces an enormous variety of custom nameplates in all the materials, thickness and finishes you need.

Anodized Aluminum Placards

Asset Tags

Metalphoto Plates

Laser Etched Plates

UID, Barcode and Serialized Plates

Custom Nameplates FAQ’s

What are the common materials used for custom nameplates?

Custom manufactured nameplates can be made from various materials, including metals like aluminum, stainless steel, brass, and bronze. Additionally, materials such as acrylic, polycarbonate, and plastic can be used for nameplate production.

How do I choose the right size and shape for my custom nameplate?

The size and shape of a custom nameplate depend on several factors, including its intended use and the available space for installation. Consider the visibility requirements, the amount of information to be displayed, and any specific design preferences. Don’t worry. If you have questions the Data Graphics Team can help you determine the optimal size and shape for your custom nameplate.

Can custom nameplates be made with different colors and finishes?

Yes, custom nameplates offer a wide range of options for colors and finishes. Depending on the manufacturing process, nameplates can be anodized, painted, powder coated, or have specialty finishes like brushed, satin, or reflective surfaces.

What are the typical methods used for engraving or printing information on custom nameplates?

Engraving and printing methods vary depending on the material and desired outcome. Common engraving techniques include laser engraving, rotary engraving, or chemical etching. For printing, methods like screen printing, digital printing, or sublimation printing are often used. The choice of method depends on factors such as material compatibility, durability, and complexity of the design.

How durable are custom manufactured nameplates and what factors can affect their longevity?

Custom manufactured nameplates are designed to be durable and withstand various environmental conditions. The durability depends on the chosen material, protective coatings, and manufacturing processes used. Factors that can affect their longevity include exposure to extreme temperatures, moisture, UV radiation, chemical exposure, physical abrasion, and improper installation. Choosing high-quality materials and finishes, along with proper care and maintenance, can significantly extend the lifespan of custom nameplates.

What certifications do you have to ensure the quality of my custom nameplate job?

When you choose Data Graphics, you are choosing one of the most decorated industrial printing companies in America. We hold several certifications including ITAR, UL, ISO9001:2015 and AS9100:2016 Rev D. For more details, please see our Certifications and Policies page.

Qualified to Deliver to Your Exact Specifications